Top 10 Benefits of Using Thermal Magnetic Circuit Breakers for Electrical Safety

In the realm of electrical safety, Thermal Magnetic Circuit Breakers (TMCBs) stand out as essential components for modern electrical systems. According to the Electrical Safety Foundation International (ESFI), electrical failures account for nearly 23% of all home fires, emphasizing the dire need for reliable protective devices. TMCBs offer a dual protection mechanism, combining thermal overload protection with magnetic short-circuit protection, which makes them invaluable in safeguarding electrical circuits from potential hazards.

Expert in electrical systems safety, Dr. Emily Carter, notes, "The integration of thermal and magnetic protection in circuit breakers has significantly enhanced electrical safety and reliability." This statement highlights the evolutionary leap TMCBs represent in the industry, striking a balance between effective function and robust protection. Industry reports reveal that the adoption of TMCBs in residential and commercial applications has increased by over 30% in the last five years, driven by growing awareness of electrical safety measures and regulatory standards. As we explore the top ten benefits of using Thermal Magnetic Circuit Breakers, it becomes clear that they are not merely components, but rather pivotal fixtures in promoting safer electrical environments.

Overview of Thermal Magnetic Circuit Breakers and Their Functionality

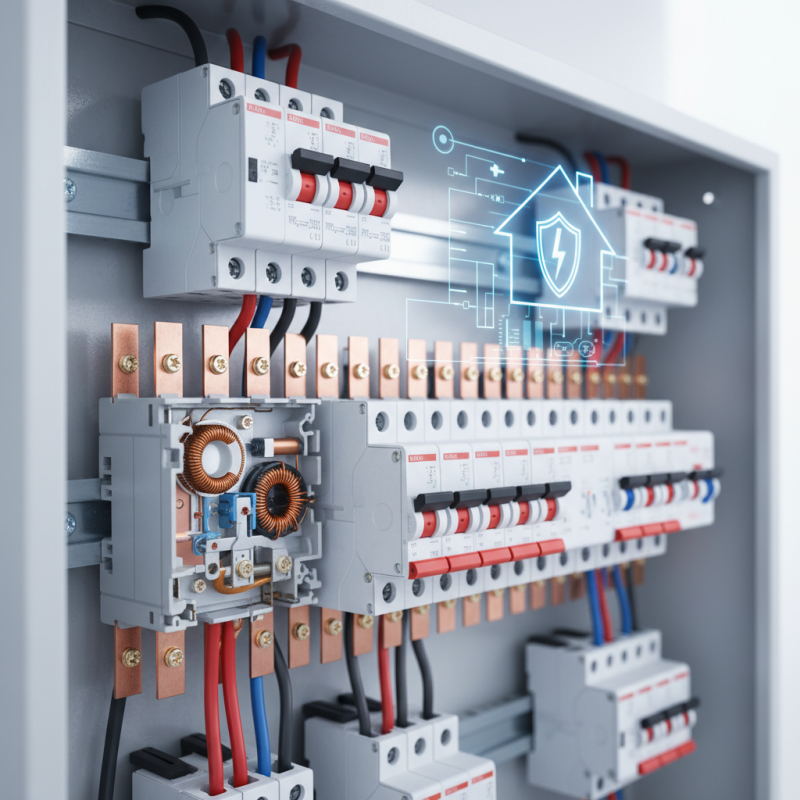

Thermal magnetic circuit breakers are essential components in modern electrical systems, designed to protect electrical circuits from overloads and short circuits. They combine two mechanisms to ensure safety: thermal and magnetic. The thermal element operates through a bimetallic strip that bends when heated by an overload current, eventually tripping the circuit. This provides a reliable way to prevent damage from excessive current over time. Conversely, the magnetic mechanism responds to rapid surges in current, such as those caused by short circuits, activating instantly to disrupt the circuit and prevent further hazards.

The functionality of thermal magnetic circuit breakers makes them highly favored in various applications, ranging from residential buildings to industrial installations. The dual-action design not only enhances electrical safety but also offers maintenance advantages, as they can be easily reset after tripping. Furthermore, their compact size and efficiency allow for optimized space usage in electrical panels, making them a practical choice for diverse installations. Overall, the integration of thermal and magnetic principles in these circuit breakers ensures robust protection and reliability in electrical safety protocols.

Key Advantages of Thermal Magnetic Circuit Breakers for Electrical Systems

Thermal magnetic circuit breakers are essential components in modern electrical systems, offering key advantages that significantly enhance electrical safety. One of the primary benefits of these devices is their dual protection mechanism. The thermal element provides overcurrent protection, while the magnetic element safeguards against short circuits. This two-pronged approach ensures that circuits remain safe under various loading conditions, effectively preventing potential hazards like electrical fires or equipment damage.

Another key advantage of thermal magnetic circuit breakers is their reliability and ease of use. They feature a resettable mechanism, allowing for quick restoration of power after a fault has been cleared. This not only minimizes downtime but also simplifies maintenance procedures. Additionally, they come in compact designs, making them suitable for various applications, from residential to industrial settings.

Their ability to provide precise and timely responses to electrical anomalies further enhances the overall reliability of electrical systems, ensuring uninterrupted power delivery while prioritizing user safety.

Comparison of Thermal Magnetic Circuit Breakers and Other Breaker Types

Thermal magnetic circuit breakers combine the functions of thermal protection and magnetic trip mechanisms, making them a popular choice in the electrical safety landscape. Compared to other circuit breaker types, such as standard thermal or solely magnetic breakers, thermal magnetic breakers provide a more well-rounded protection strategy. According to a report from the International Electrotechnical Commission (IEC), the multi-faceted approach of thermal magnetic breakers enables faster response times to overload and short-circuit conditions, reducing the risk of damage to electrical systems and enhancing overall safety.

In contrast, traditional thermal circuit breakers respond to overloads but can be slower in reacting to short-circuit scenarios, potentially allowing harmful conditions to develop. On the other hand, magnetic breakers respond swiftly to such scenarios but lack the sensitivity to gradual overloads. A study published in the Journal of Electrical Engineering indicates that systems integrating thermal magnetic circuit breakers show up to a 30% decrease in equipment failure rates compared to systems using only thermal or magnetic breakers. This adaptability not only improves safety but also reduces maintenance costs over time, making thermal magnetic options highly effective for both residential and industrial applications.

Safety Enhancements Provided by Thermal Magnetic Circuit Breakers

Thermal magnetic circuit breakers are essential components in modern electrical systems, providing dual protection mechanisms that significantly enhance safety. The thermal element of these breakers is designed to respond to prolonged overloads, effectively preventing potential overheating and electrical fires. By sensing the gradual increase in current, the thermal mechanism allows for a timely disconnection of the circuit, ensuring that excessive current does not lead to dangerous conditions.

On the other hand, the magnetic component responds instantaneously to short circuits, which can cause catastrophic damage within fractions of a second. This rapid response ability is crucial in protecting both equipment and personnel from the adverse effects of electrical faults. Together, these two features create a robust safety net, offering dual-layer protection that significantly reduces the risk of electrical hazards. The incorporation of thermal magnetic circuit breakers in electrical systems thus transforms safety measures, making environments more secure for users and minimizing potential damage from electrical failures.

Top 10 Benefits of Using Thermal Magnetic Circuit Breakers for Electrical Safety

Applications and Best Practices for Using Thermal Magnetic Circuit Breakers

Thermal magnetic circuit breakers are essential components in electrical systems, providing reliable protection against overcurrent faults. Their dual functionality allows them to safeguard circuits from both overload and short-circuit conditions. In practice, these breakers are used in various applications, including residential, commercial, and industrial settings. For instance, in residential buildings, they are typically installed in the main electrical panel to protect household wiring and prevent potential fire hazards caused by overloaded circuits. In industrial applications, they help to protect heavy machinery and prevent costly downtime caused by electrical faults.

Best practices for using thermal magnetic circuit breakers involve proper sizing and installation to ensure optimal protection. Selecting the right amperage rating based on the expected load is crucial. It is essential to consider both continuous and peak load conditions during selection. Additionally, proper installation techniques, such as ensuring secure connections and correct mounting, can significantly enhance the performance of these breakers. Regular maintenance, including routine testing and inspection, helps identify any potential issues before they lead to system failures, thereby ensuring the ongoing reliability of electrical installations. By following these best practices, users can maximize the effectiveness of thermal magnetic circuit breakers and enhance overall electrical safety.

Related Posts

-

How to Choose the Right Air Circuit Breaker for Your Electrical System

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

-

2025 Market Insights: The Future of Best Thermal Magnetic Circuit Breakers

-

Unmatched Excellence in Manufacturing by Leading Chinese Factory for Best Electrical MCCB Solutions

-

The Future of Innovative Energy Management with Best Air Circuit Breakers

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500