Top 10 Tips for Choosing the Right Thermal Magnetic Circuit Breaker

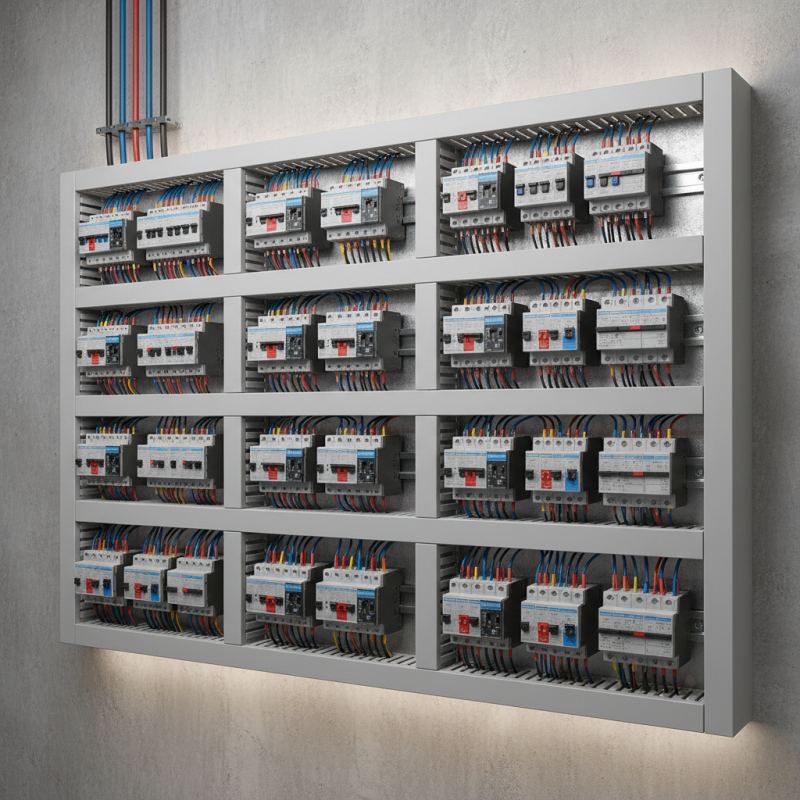

In an age where electrical safety and efficiency are paramount, selecting the right Thermal Magnetic Circuit Breaker (TMCB) is crucial for both residential and industrial applications. According to John Smith, a leading expert in electrical engineering, “The choice of a Thermal Magnetic Circuit Breaker can significantly impact the reliability and safety of your electrical systems.” This statement underscores the importance of understanding the various factors involved in the selection process of these essential components.

Thermal Magnetic Circuit Breakers serve a dual purpose: they provide overload protection through thermal mechanisms and short-circuit protection via magnetic mechanisms. As the demand for reliable electrical systems continues to grow, recognizing the nuances of TMCBs is vital. A well-chosen circuit breaker not only safeguards equipment but also can enhance overall system performance and longevity. In this guide, we will explore the top ten tips for selecting the right Thermal Magnetic Circuit Breaker, equipping you with the knowledge needed to make informed decisions that contribute positively to both safety and efficiency.

Understanding Thermal Magnetic Circuit Breakers and Their Functionality

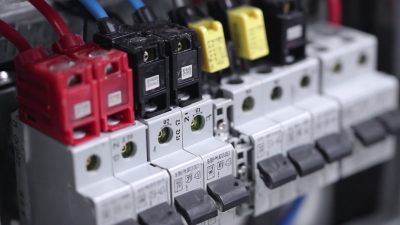

Thermal magnetic circuit breakers are essential devices designed to protect electrical circuits from overloads and short circuits. Their dual functionality combines thermal and magnetic protection: the thermal element reacts to gradual overload conditions, while the magnetic element responds to sudden surges. This two-pronged approach ensures reliable performance and safety in various electrical applications, making understanding their features crucial when selecting the right model for your needs.

When choosing a thermal magnetic circuit breaker, consider the current ratings suitable for your specific applications. Ensure that the breaker's rating aligns with the load requirements; an underrated breaker may trip frequently, while an overrated one may not provide adequate protection. Additionally, assess the mounting options available, as installation space can significantly influence your choice.

Another important aspect to evaluate is the trip characteristics of the breaker. Different applications may require slow or fast trip responses based on the load type and sensitivity. Understanding these characteristics will help in selecting a breaker that offers optimal protection without unnecessary interruptions. By taking these factors into account, you can ensure that the thermal magnetic circuit breaker you select will effectively guard your electrical systems against potential hazards.

Identifying Key Specifications When Selecting a Circuit Breaker

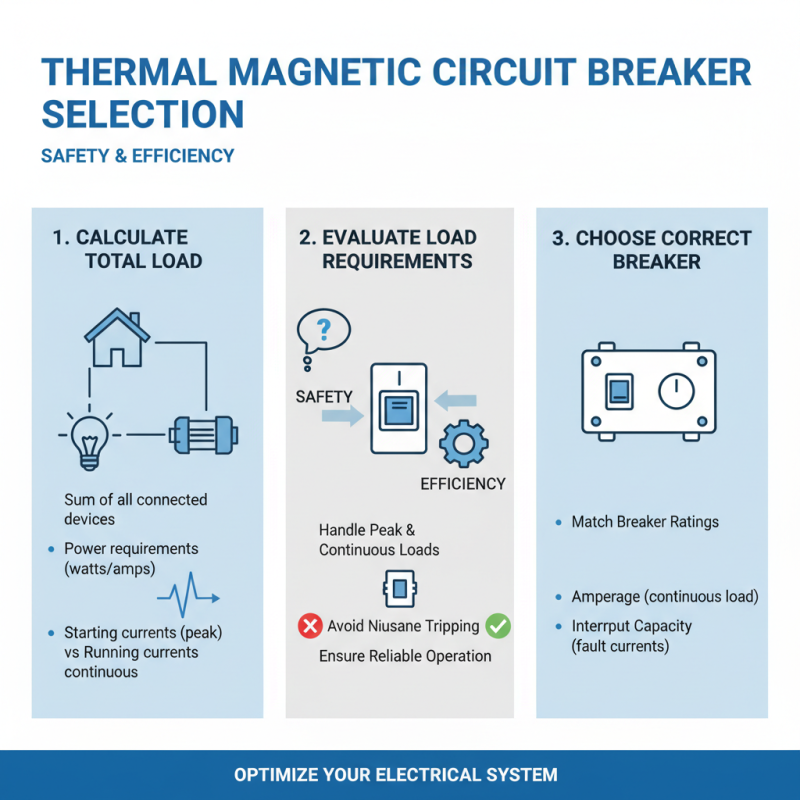

When selecting the right thermal magnetic circuit breaker, understanding key specifications is essential to ensuring you meet your electrical requirements safely and effectively. One critical specification to consider is the breaker’s current rating, which should align with your system’s maximum expected load. This ensures that the breaker will trip under overcurrent conditions, protecting your circuit from damage due to overloads or short circuits.

Another important factor is the interrupting capacity, which indicates the maximum fault current the breaker can safely interrupt without failing. Choosing a breaker with an appropriate interrupting capacity is vital for the safety of your installation. Additionally, consider the voltage rating of the circuit breaker. It must be compatible with the voltage of your electrical circuit to maintain effective performance and safety standards.

When making your selection, remember to take into account the physical dimensions and mounting options of the circuit breaker. Ensure that it fits well within your existing panel space and complies with your installation requirements. These considerations will help you find a thermal magnetic circuit breaker that not only meets your technical needs but also contributes to the overall reliability and efficiency of your electrical system.

Top 10 Tips for Choosing the Right Thermal Magnetic Circuit Breaker

Evaluating the Load Requirements for Your Electrical System

When selecting a thermal magnetic circuit breaker, evaluating the load requirements of your electrical system is crucial to ensure safety and efficiency. Start by calculating the total load that your system will handle. This involves assessing the power requirements of all connected devices and equipment. Consider factors like starting currents, which can be significantly higher than running currents for some machinery. Accurately understanding these parameters helps in choosing a circuit breaker that can handle both peak and continuous loads without tripping unnecessarily.

Next, it’s important to consider the future needs of your system. Electrical demand can change due to expansions or additional equipment. Therefore, select a thermal magnetic circuit breaker that not only meets your current requirements but also has a capacity to accommodate potential increases in load. This foresight can save time and money by avoiding premature upgrades or replacements of circuit protection devices. Keep in mind the specific characteristics of your electrical environment, such as the presence of sensitive electronics that may require more specialized protection features. By thoroughly evaluating these load requirements, you can make a more informed decision that ensures long-lasting and reliable operation of your electrical system.

Assessing Environmental Conditions Affecting Circuit Breaker Performance

When selecting a thermal magnetic circuit breaker, one crucial aspect to consider is the environmental conditions that can significantly influence its performance. Circuit breakers are commonly exposed to varying temperatures, humidity levels, and even dust or corrosive agents, all of which can affect their reliability and effectiveness. For instance, extreme temperatures can lead to premature tripping or failure to trip when needed. Therefore, understanding the specific environment where the circuit breaker will be installed is essential for optimal operation.

Additionally, moisture and humidity can introduce risks such as condensation, which can lead to short circuits or corrosion of the internal components of the breaker. It is important to assess whether the installation area is prone to high humidity, and if necessary, choose circuit breakers that offer better sealing or protection against moisture ingress. Dust accumulation is another factor; circuit breakers installed in dirty environments may require more frequent maintenance or specific protective features to prevent malfunctions. By carefully evaluating these environmental conditions, one can ensure the right circuit breaker is chosen to maintain system safety and efficiency.

Top 10 Tips for Choosing the Right Thermal Magnetic Circuit Breaker - Assessing Environmental Conditions Affecting Circuit Breaker Performance

| Tip | Description | Environmental Condition | Impact on Performance |

|---|---|---|---|

| 1. Consider Temperature Range | Select breakers that can operate efficiently within the expected temperature variations. | High/Low Temperature | Improper operation or tripping. |

| 2. Assess Humidity Levels | Choose circuit breakers designed for high humidity environments to avoid corrosion. | High Humidity | Corrosion may lead to failure. |

| 3. Evaluate Dust Levels | Choose enclosures that provide adequate protection against dust ingress. | Dusty Environments | Dust accumulation can cause overheating. |

| 4. Check Altitude Effects | Higher altitudes can affect insulation performance; select suitable breakers. | High Altitudes | Reduced insulation could lead to failure. |

| 5. Consider Vibration and Shock | Look for circuit breakers with vibration resistance for industrial settings. | Vibrating Machinery | Risk of mechanical failure. |

| 6. Identify Chemical Exposure | Ensure that the materials used can withstand potential chemical exposure. | Chemical Environments | Corrosion leading to malfunction. |

| 7. Analyze Electrical Load Characteristics | Select breakers rated for the specific load type and operating conditions. | Variable Electrical Loads | Overloading may cause tripping. |

| 8. Consider Installation Environment | Evaluate the environment where the breaker will be installed for susceptibility. | Indoor/Outdoor Installations | Improper functioning due to conditions. |

| 9. Review Regulatory Standards | Ensure compliance with local and international electrical standards. | Regulatory Compliance | Non-compliance could lead to penalties. |

| 10. Evaluate Maintenance Needs | Choose circuit breakers that are easy to maintain and inspect. | Maintenance Environment | Difficult maintenance can lead to neglect. |

Comparing Different Brands and Models for Quality Assurance

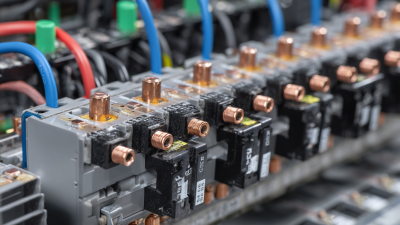

When selecting a thermal magnetic circuit breaker, the quality assurance associated with different brands and models can significantly influence performance and reliability. Industry reports indicate that thermal magnetic circuit breakers account for over 45% of the total market share in electrical protection devices, highlighting their importance. Studies have shown that choosing a breaker with proven reliability can minimize the risk of electrical failures. Analyzing test results, certification data, and user reviews can provide insight into a product's longevity and efficiency.

In particular, one tip for ensuring quality is to look for products that meet or exceed the International Electrotechnical Commission (IEC) standards. Breakers that are IEC-compliant typically undergo rigorous testing, ensuring they perform effectively under various conditions. Additionally, examining the thermal characteristics, such as the tripping curve, can help assess how quickly the breaker responds to overload or short-circuit conditions, which is critical for safeguarding sensitive equipment.

Another important consideration is the brand’s reputation for customer service and support. A manufacturer that provides comprehensive documentation, installation guides, and responsive customer service can enhance the overall experience and ensure proper usage of the device. Research shows that brands with robust support systems often have lower return rates and higher customer satisfaction, directly impacting their market competitiveness. Taking into account these aspects will aid in selecting a circuit breaker that not only fits the technical requirements but also guarantees ongoing support and reliability in the long term.

Related Posts

-

Understanding Thermal Magnetic Circuit Breakers: How They Protect Your Electrical Systems

-

Ultimate Guide to Understanding Molded Case Breakers for Your Electrical Needs

-

Understanding the Advantages of Using Electronic Circuit Breakers in Modern Electrical Systems

-

Understanding the Importance of Acb Circuit Breakers in Modern Electrical Systems

-

12 Reasons Why Best Electronic MCCB Should Be Your Top Choice

-

10 Amazing Reasons Why Electronic MCCBs Are Essential for Your Business

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500