Understanding Thermal Magnetic Circuit Breakers: How They Protect Your Electrical Systems

In today's rapidly evolving electrical landscape, safeguarding your systems from overloads and short circuits is crucial for maintaining functionality and safety. One effective solution is the Thermal Magnetic Circuit Breaker, a device that combines the principles of thermal and magnetic protection to ensure reliable operation. This guide aims to delve into the workings of Thermal Magnetic Circuit Breakers, exploring their essential roles and advantages in circuit protection. We'll cover how these breakers operate under different electrical conditions, their installation processes, and best practices for maintenance. Understanding these components is vital for anyone involved in electrical planning, installation, or troubleshooting, as their proper implementation can prevent costly damages and enhance the longevity of your electrical systems. Join us as we navigate through the intricacies of Thermal Magnetic Circuit Breakers and empower yourself with the knowledge necessary to protect your electrical infrastructure.

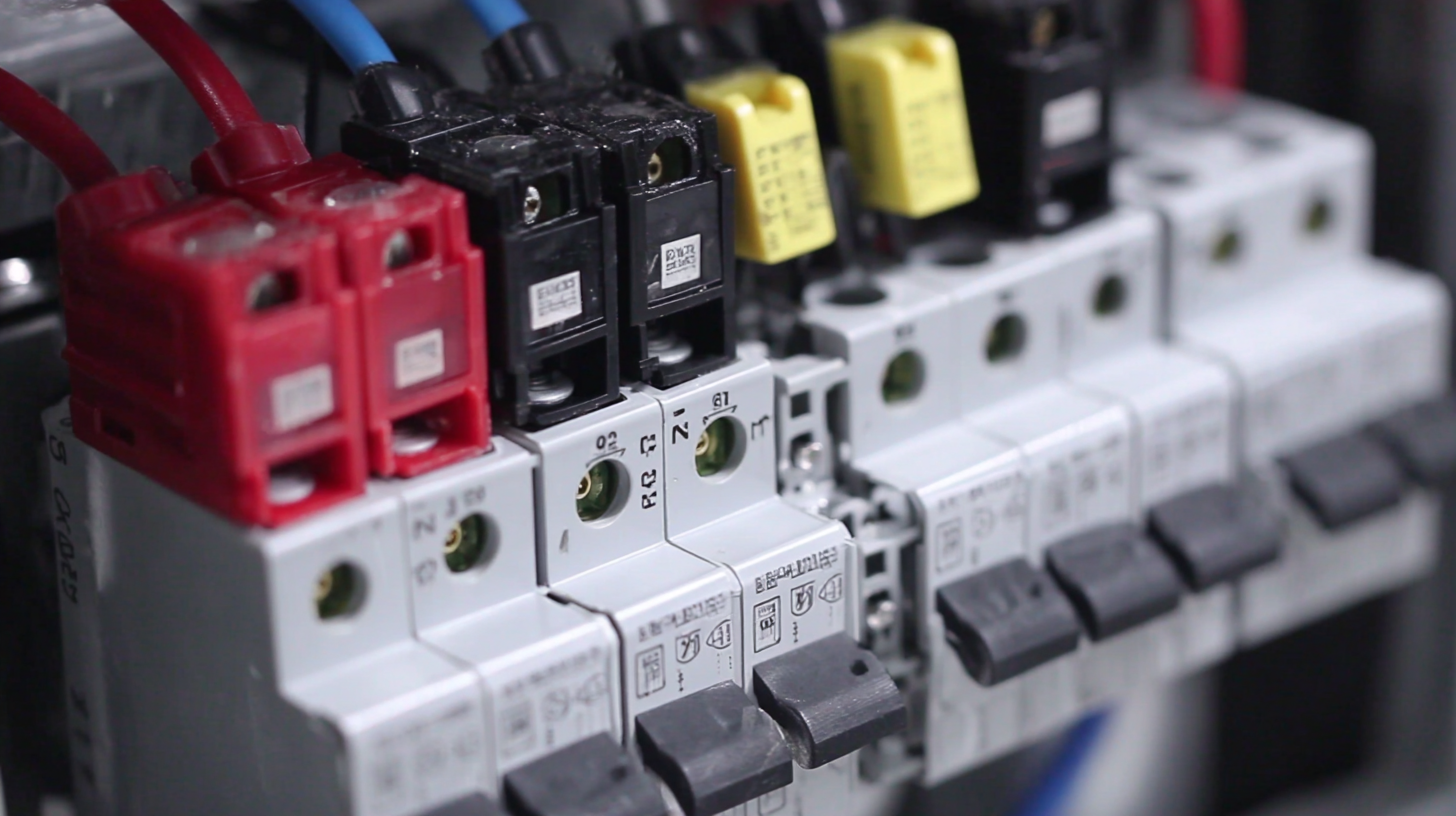

Types of Thermal Magnetic Circuit Breakers and Their Functions

Thermal magnetic circuit breakers are essential components designed to protect electrical systems from overloads and short circuits. There are two primary types of thermal magnetic circuit breakers: the thermal trip and the magnetic trip.

The thermal trip mechanism utilizes a bimetallic strip that bends when it heats up, which occurs during a prolonged overload condition. This bending action triggers the circuit breaker to open, thus interrupting the current flow and preventing potential damage to the electrical system.

On the other hand, the magnetic trip mechanism reacts instantaneously to short circuit conditions. It employs an electromagnet that becomes energized when a high current flows through the circuit. This surge creates a magnetic force strong enough to pull the circuit breaker’s lever, swiftly disconnecting the circuit. This dual-action design of thermal magnetic circuit breakers ensures comprehensive protection against different fault conditions, making them a reliable choice for various applications in residential, commercial, and industrial settings.

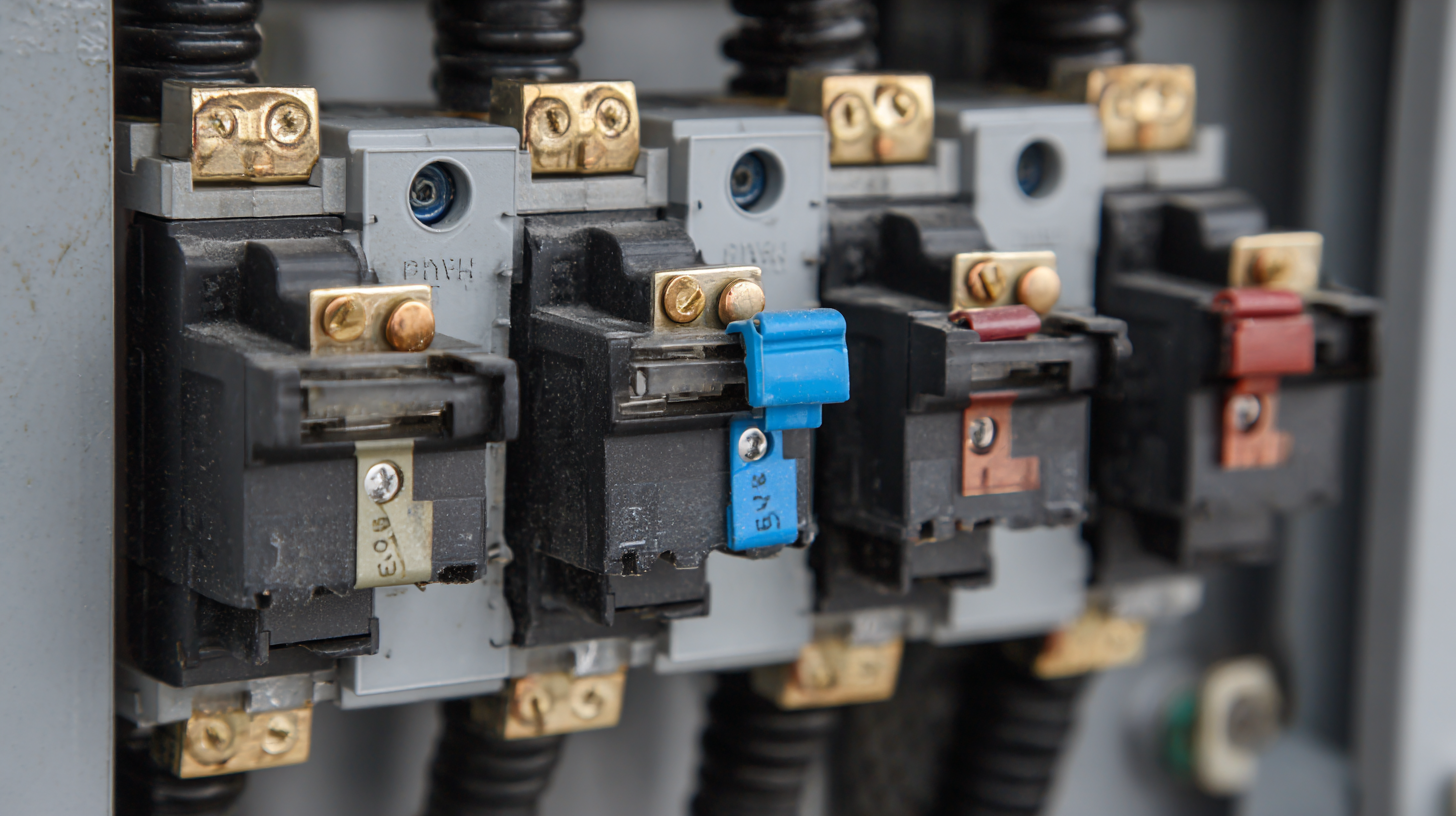

Key Components of Thermal Magnetic Circuit Breakers

Thermal magnetic circuit breakers are essential devices that ensure the protection and reliability of electrical systems. Understanding the key components of these breakers provides insight into how they function effectively. The two primary elements of thermal magnetic circuit breakers are thermal protection and magnetic protection, each serving distinct purposes in fault conditions.

Thermal magnetic circuit breakers are essential devices that ensure the protection and reliability of electrical systems. Understanding the key components of these breakers provides insight into how they function effectively. The two primary elements of thermal magnetic circuit breakers are thermal protection and magnetic protection, each serving distinct purposes in fault conditions.

The thermal component utilizes a bimetallic strip that bends under heat generated by an overload condition. When the current exceeds a predetermined threshold, the strip heats up, eventually causing the circuit breaker to trip and disconnect the electrical supply. This response is crucial in preventing overheating and potential fire hazards.

In contrast, the magnetic protection mechanism responds to short circuits. It employs an electromagnet that activates almost instantly when a surge is detected, rapidly tripping the breaker to prevent damage to the electrical system. This dual-action approach ensures comprehensive protection, allowing thermal magnetic circuit breakers to manage both gradual overloads and sudden spikes in current, safeguarding equipment and circuits effectively.

How Thermal Magnetic Circuit Breakers Operate in Electrical Systems

Thermal magnetic circuit breakers are essential components in modern electrical systems, providing dual protection against overloads and short circuits. The thermal mechanism operates by using a bimetallic strip that bends in response to heat generated by excess current, while the magnetic part reacts quickly to short circuit conditions, offering instantaneous disconnection. This dual-response capability is crucial, as it balances the need for reliable protection with the ability to maintain system functionality during normal overload conditions. According to the International Electrotechnical Commission, more than 30% of electrical system failures are attributed to inadequate protection mechanisms, emphasizing the importance of robust circuit breakers.

In practical applications, thermal magnetic circuit breakers offer significant advantages in various settings, from residential to industrial. For example, a report by the National Fire Protection Association highlights that nearly half of all electrical fires originate from circuit overloading. The integration of thermal and magnetic protection mitigates this risk by ensuring that circuits are disabled before damage can occur. Furthermore, as electrical systems grow more complex with the integration of renewable energy sources, the need for reliable circuit protection becomes even more critical. Thus, selecting high-quality thermal magnetic circuit breakers is essential for safeguarding both personnel and equipment across a wide range of applications.

Understanding Thermal Magnetic Circuit Breakers: How They Protect Your Electrical Systems

| Feature | Description | Function | Application |

|---|---|---|---|

| Thermal Protection | Responds to overcurrent conditions by sensing heat generated by excess current | Prevents overheating of electrical systems | Used in residential, commercial, and industrial settings |

| Magnetic Protection | Instantly trips during short circuit conditions | Protects against abrupt current surges | Important for high-power applications and motor circuits |

| Manual Reset | Requires user intervention to reset after tripping | Ensures that users check for issues before restarting | Used in low-voltage applications |

| Adjustable Tripping | Allows users to set the trip current levels | Customizes protection according to load requirements | Common in industrial processes with variable loads |

| Compact Design | Minimizes space requirements in electrical panels | Facilitates easier installations | Suitable for modern, space-constrained environments |

Advantages of Using Thermal Magnetic Circuit Breakers for Protection

Thermal magnetic circuit breakers offer a robust solution for protecting electrical systems from overloads and short circuits. Their dual mechanism combines thermal and magnetic protection, which allows them to respond effectively to different fault conditions. The thermal element reacts to overload currents, providing a time-delay effect that prevents nuisance tripping during temporary surges. In contrast, the magnetic component acts instantaneously to disconnect the circuit during short circuits, ensuring immediate protection of the system and connected devices.

One of the primary advantages of using thermal magnetic circuit breakers is their reliability and versatility. They are suitable for various applications, from residential to industrial settings, providing essential protection while being able to handle diverse load types. Additionally, these breakers are easy to reset after tripping, minimizing downtime and maintenance costs. Their ability to provide both overload and short circuit protection in a single unit simplifies system design and enhances safety, making them a preferred choice for electrical engineers and contractors.

Common Applications of Thermal Magnetic Circuit Breakers in Industry

Thermal magnetic circuit breakers are widely utilized in various industrial applications due to their dual protection mechanism against overloads and short circuits. In manufacturing facilities, these breakers play a critical role in safeguarding machinery and equipment from damage caused by excessive currents. For instance, in assembly lines where heavy machinery is employed, a thermal magnetic circuit breaker ensures that any surge in electrical flow, often caused by motor startup or equipment failure, can be quickly interrupted, thus preventing costly downtime and equipment repair.

In commercial settings, these circuit breakers are commonly found in electrical panels to protect entire systems, including HVAC units, lighting circuits, and power distribution networks. Their ability to detect both thermal overloads and short circuits makes them invaluable in environments where varying load conditions are present. Hospitals, data centers, and educational institutions also rely on thermal magnetic circuit breakers to enhance the safety and reliability of their electrical systems, ensuring uninterrupted operation while minimizing the risk of electrical fires or equipment malfunctions.

Related Posts

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

Ultimate Guide to Selecting the Right Air Circuit Breaker for Your Industrial Needs

-

How to Choose the Right Molded Case Circuit Breaker for Your Electrical Needs

-

7 Best Features of Square D MCCB for Optimal Electrical Protection

-

Understanding Common Issues Faced with Best MCCB Moulded Case Circuit Breakers

-

The Evolution of Molded Case Circuit Breakers in a Global Market

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500