How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

Selecting the right MCCB molded case circuit breaker is crucial for ensuring the safety and efficiency of electrical systems in various applications. According to the latest industry report by Technavio, the global molded case circuit breaker market is projected to grow at a CAGR of 5.4% from 2021 to 2025, reflecting the increasing demand for reliable circuit protection solutions in industrial and commercial sectors. With rising energy consumption and the need for enhanced safety measures, understanding the specifications and features of MCCB molded case circuit breakers becomes essential. These breakers not only provide overcurrent protection but also cater to the diverse requirements of different electrical systems. Therefore, selecting the appropriate MCCB molded case circuit breaker tailored to your system's specific needs is imperative for optimizing performance and reliability while ensuring compliance with current safety standards and regulations.

Understanding the Basics of MCCB and Its Importance in Electrical Systems

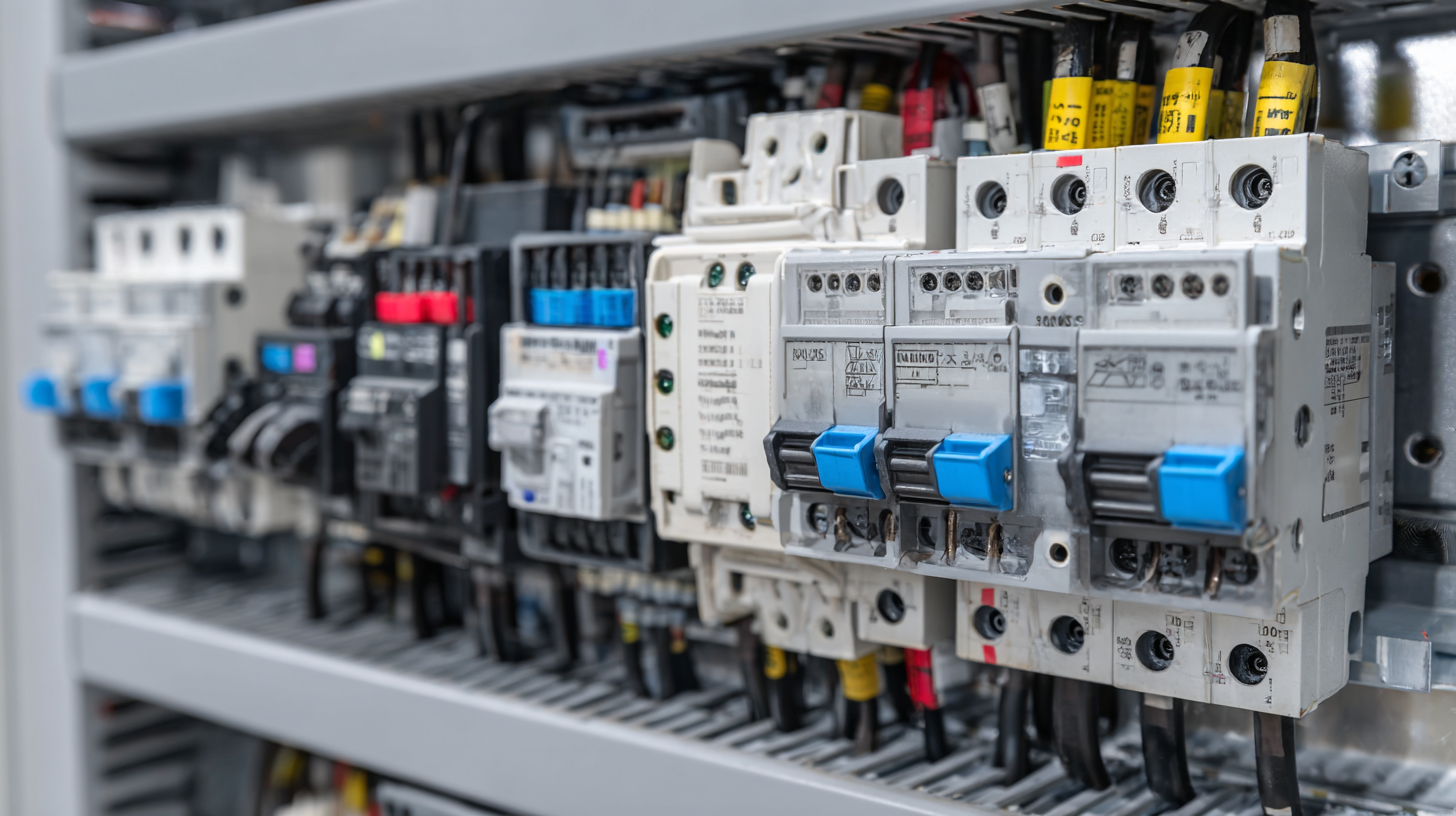

Molded Case Circuit Breakers (MCCBs) play a crucial role in electrical systems by providing overcurrent protection and circuit interruption capabilities. Understanding the basics of MCCBs is essential for anyone involved in electrical design or maintenance. MCCBs are designed to protect wiring and equipment by disconnecting power in the event of an overload or short circuit, thus preventing potential damage and hazards. They come in various sizes and ratings, making them suitable for diverse applications, from commercial buildings to industrial settings.

The importance of MCCBs in electrical systems cannot be overstated. They ensure operational safety by preventing overheating and component failure, which can lead to costly downtime or catastrophic failures. Moreover, MCCBs are equipped with adjustable trip settings, allowing for customization according to specific system requirements. This flexibility makes them an integral part of modern electrical infrastructure, offering efficiency and reliability. Understanding these aspects not only aids in selecting the appropriate MCCB but also contributes to the overall safety and longevity of the electrical system.

Identifying the Key Specifications for Your MCCB Selection

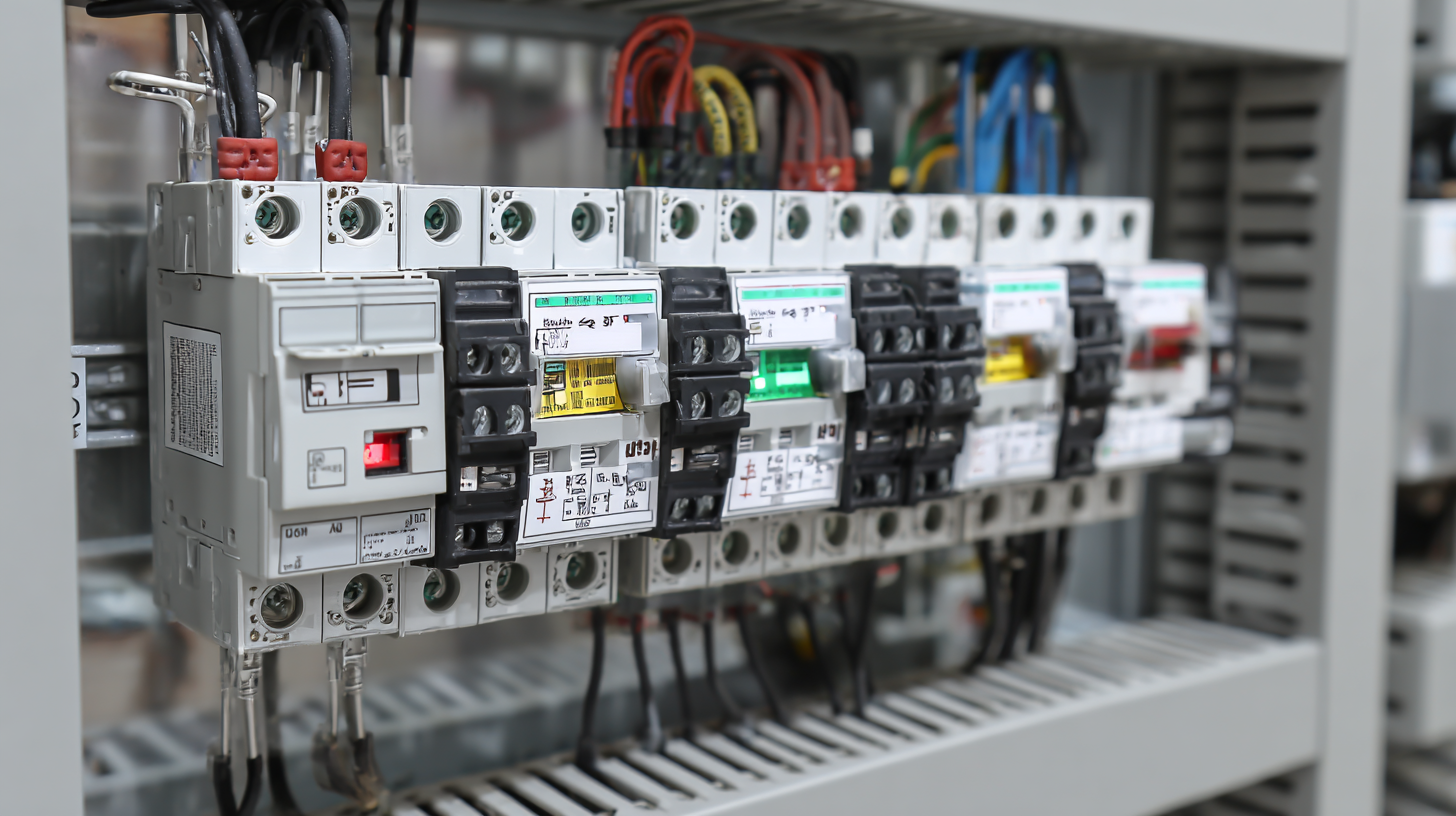

When selecting the right Molded Case Circuit Breaker (MCCB) for your electrical system, understanding the key specifications is crucial. Firstly, you’ll need to determine the rated current, which indicates the maximum continuous current the MCCB can handle. This value should be based on the load calculations of your electrical system. Always choose an MCCB rated slightly above your calculated load to account for fluctuations and potential future expansions.

Additionally, consider the breaking capacity of the MCCB, which is the maximum fault current it can safely interrupt without damage. This specification is vital for ensuring safety and operational reliability. Look for an MCCB that matches or exceeds the prospective short-circuit current of your system.

Tips to Remember: Choose an MCCB with adjustable settings if your system experiences varying loads frequently. This feature allows you to fine-tune the breaker to optimize protection. Also, consider environmental factors such as temperature and humidity, as they may influence the performance and longevity of the circuit breaker.

Evaluating Environmental Factors That Affect MCCB Performance

When selecting a molded case circuit breaker (MCCB) for your electrical system, it is crucial to assess the environmental factors that may impact its performance. Temperature variations can significantly affect the breaker’s operation, as MCCBs are designed to operate within specific temperature ranges. If the breaker is exposed to extreme heat or cold, it may not trip effectively, leading to potential overloads or faults. Always consider the maximum and minimum temperatures of the installation site to ensure reliability.

Humidity and moisture are also critical factors. High humidity can lead to corrosion of electrical components and increase the risk of insulation failure. Conversely, excessively dry conditions can create static electricity, which may induce faults under certain circumstances. Ensure that the MCCB is rated for the environmental conditions it will face, and consider enclosure options that provide protection against moisture and dust ingress.

**Tips:**

1. Always check the manufacturer's specifications for operating temperature and humidity ranges.

2. Utilize enclosures designed for specific environmental conditions, such as waterproof or dustproof models, to ensure longevity and reliability of the MCCB.

3. Consider additional protective devices if the installation site has extreme environmental conditions that could potentially affect the MCCB's functioning.

Comparing Different Types of MCCBs Based on Your Application Needs

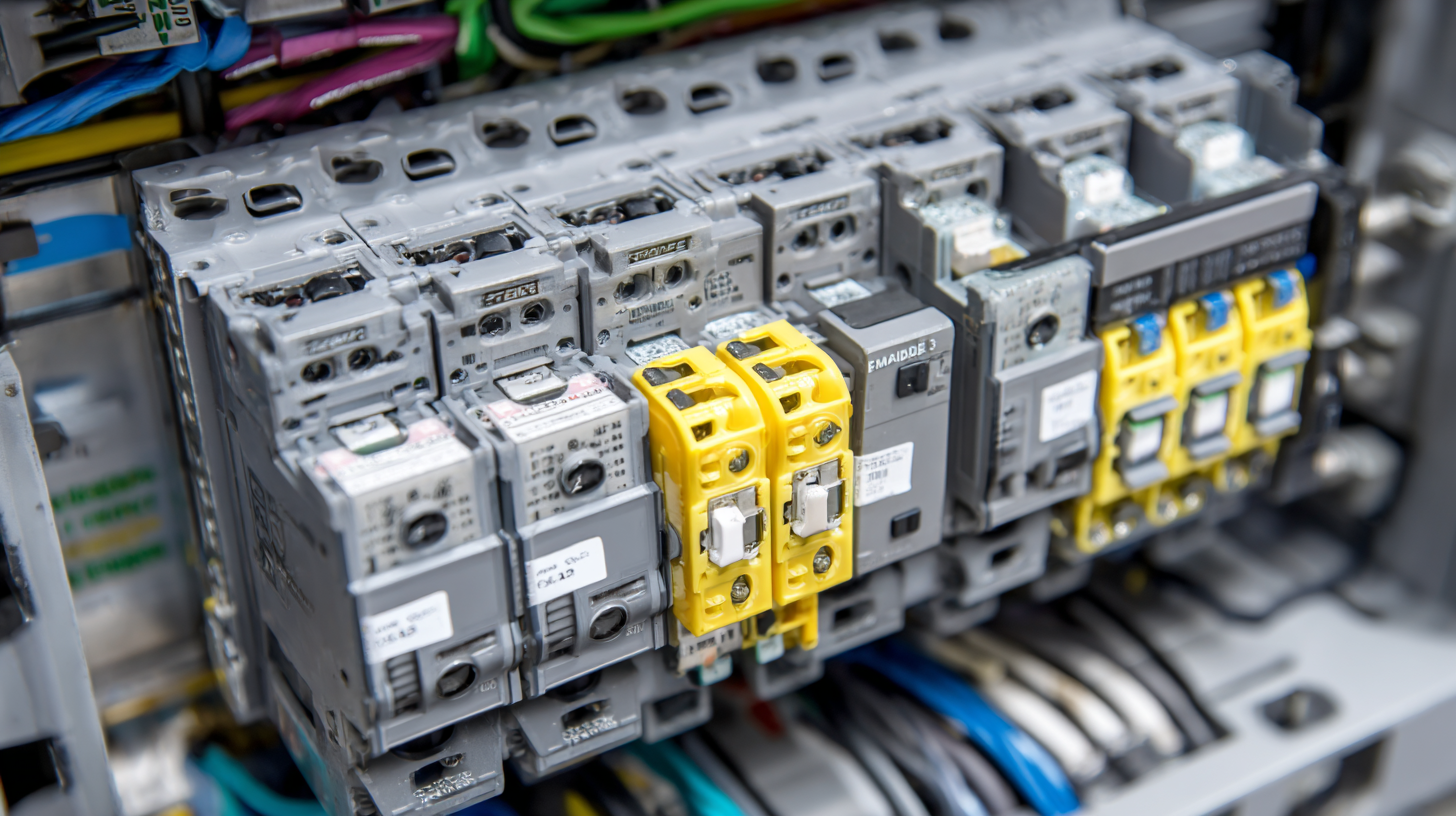

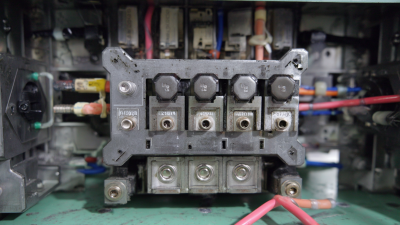

When selecting the right molded case circuit breaker (MCCB) for your electrical system, it's crucial to consider the specific application needs of your installation. Different types of MCCBs are designed to suit varying voltage levels, current ratings, and environmental conditions. Modern offerings, such as modular systems, provide flexibility and adaptability through a wide range of accessory components, enabling customization to meet unique operational demands.

For applications like higher-voltage solar power plants, specialized MCCBs are engineered to handle increased electrical loads while ensuring safety and reliability. The evolution of MCCB technology also emphasizes protective features that are essential for preventing overloads and short circuits, ultimately safeguarding your electrical infrastructure. With an increasing demand projected in the market, these advancements underline the importance of selecting the right MCCB according to specific requirements, whether for industrial, commercial, or residential use.

Ensuring Compliance with Safety Standards and Regulations in MCCB Selection

When selecting a Molded Case Circuit Breaker (MCCB), ensuring compliance with safety standards and regulations is paramount. According to the International Electrotechnical Commission (IEC) standards, MCCBs must adhere to stringent guidelines to ensure both operational reliability and safety in electrical systems. For example, IEC 60947-2 provides essential criteria regarding the performance, maintenance, and testing of MCCBs, specifically focusing on factors such as short-circuit protection, overload characteristics, and environmental considerations.

In the United States, the National Electrical Manufacturers Association (NEMA) further emphasizes the importance of compliance with UL 489 standards, which govern the safety requirements for molded case circuit breakers. These regulations not only help prevent electrical hazards but also ensure that MCCBs are capable of interrupting fault conditions effectively. Industry reports indicate that non-compliance can lead to significant risks, including equipment damage and potential safety hazards, underscoring the necessity of diligent adherence to these standards. Therefore, when selecting an MCCB, it is critical to verify that the chosen breaker meets all relevant safety standards to safeguard both personnel and equipment within the electrical system.

Related Posts

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

Unmatched Excellence in Manufacturing by Leading Chinese Factory for Best Electrical MCCB Solutions

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

-

Navigating Global Compliance: Import and Export Certifications for Best MCCB Moulded Case Circuit Breakers

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500