What is a Molded Case Breaker and How Does it Work?

In the world of electrical engineering, understanding a Molded Case Breaker is crucial. As John Smith, a leading expert in circuit protection, states, “The Molded Case Breaker is the backbone of modern electrical safety.” This device safeguards equipment and people from overloads and short circuits. Its design offers reliability and ease of use, making it a staple in industrial settings.

Molded Case Breakers come in various sizes and specifications. Each model caters to specific electrical needs. They are housed in durable casings that withstand harsh industrial environments. This ensures protection against physical damage and dust. Yet, many users overlook the importance of regular testing and maintenance. Ignoring these aspects can lead to equipment failure.

The intricate workings of a Molded Case Breaker involve electromagnetic and thermal triggers. The electromagnetic component responds to immediate surges, while the thermal element reacts to prolonged overloads. Balance is key. However, understanding this balance can be challenging for many. While some may feel confident in their knowledge, it is essential to continually educate oneself on the latest advancements in technology and safety standards.

What is a Molded Case Breaker?

A molded case breaker (MCB) is an essential component in electrical systems. It protects circuits from overloads and short circuits. Unlike fuses, which must be replaced after a fault, MCBs can be reset. This feature makes them convenient for everyday use.

MCBs contain an electromagnetic mechanism that reacts quickly to high currents. When an overload occurs, the mechanism trips the circuit. Users often appreciate this feature, yet sometimes forget to reset it. This can lead to unnecessary downtime.

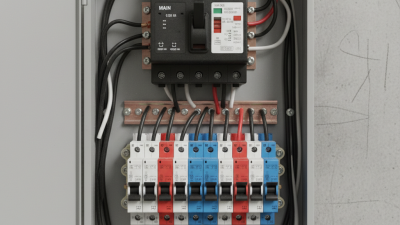

The design of molded case breakers allows them to fit into various panels. They come in different current ratings and trip settings. However, choosing the right one may require careful consideration. Some users may install MCBs without adequate knowledge, which can lead to mistakes. It's crucial to understand their ratings and functions to ensure safety and reliability.

Key Components of Molded Case Breakers

Molded case breakers are essential in electrical systems. They protect circuits from overloads and short circuits. Understanding their key components is crucial for proper application.

The main parts include the breaking mechanism, thermal trip element, and magnetic trip element. The breaking mechanism interrupts the circuit. This happens when it detects an overload. The thermal trip element senses current. It reacts slowly to gradual increases in temperature. Meanwhile, the magnetic trip element responds quickly to short circuits. It provides immediate protection.

Tips: Regular maintenance is vital. Check for any signs of wear. Ensure that connections are tight. This practice can prevent costly failures. Additionally, understanding load requirements is crucial. Overloading can lead to malfunction.

Another important aspect is testing the device. Periodically test the breaker to ensure it operates correctly. Many users forget about this step. This oversight can lead to serious safety issues. Stay proactive with your electrical equipment for the best performance.

Molded Case Breaker Current Ratings

How Molded Case Breakers Operate

Molded case breakers (MCBs) are essential components in electrical distribution systems. Their primary role is to protect circuits from overload and short circuits. They combine the functions of an overload relay and a circuit breaker. The design ensures safety and efficiency in various settings, from industrial environments to residential buildings.

MCBs operate by using a mechanism that senses current flow. When the current exceeds a preset level, the device trips to interrupt the circuit. There are thermal and magnetic components involved in this tripping mechanism. In 2020, the global market for molded case circuit breakers was valued at approximately $5.5 billion, indicating their importance in electrical safety. Yet, reliability issues can arise with aging breakers. This can lead to unexpected failures during critical moments.

Regular testing and maintenance are crucial. Some reports suggest that nearly 30% of MCB failures occur due to poor maintenance practices. The National Fire Protection Association also highlights that outdated equipment increases fire risks significantly. Thus, regular checks and updates can save lives and resources. Molded case breakers must be treated as vital assets in any electrical infrastructure. Addressing their limitations can lead to safer operations and better reliability.

What is a Molded Case Breaker and How Does it Work? - How Molded Case Breakers Operate

| Aspect | Description |

|---|---|

| Definition | A Molded Case Breaker (MCB) is a type of electrical circuit breaker designed to protect electrical circuits from overloads and short circuits. |

| Operating Principle | MCBs operate by using an electromechanical mechanism that trips the circuit when current exceeds its rated limit. |

| Components | Typical components include a plunger, spring mechanism, and contacts that open or close the circuit. |

| Types of Protection | Overload protection, short circuit protection, and in some cases, earth leakage protection. |

| Applications | Used in residential, commercial, and industrial applications to safeguard electrical distribution systems. |

| Sizes | Available in various current ratings ranging from a few amperes to several thousand amperes. |

| Reset Mechanism | Most MCBs can be reset manually after tripping, allowing the circuit to be re-energized. |

| Benefits | They offer reliable protection, quick response times, and are relatively easy to install and maintain. |

Applications of Molded Case Breakers in Electrical Systems

Molded case breakers (MCBs) are crucial for electrical systems. They protect circuits from overloads and short circuits. MCBs are designed to interrupt current flow when problems arise. This helps prevent equipment damage and reduces fire risks. Their compact design allows for easy integration into various systems.

In industrial settings, MCBs play a vital role. They safeguard machinery and ensure operational safety. Restaurants and hotels rely on them for kitchen equipment. Residential buildings also benefit from MCBs for home appliances. Each application demands reliability and efficiency.

However, regular maintenance is often overlooked. MCBs can wear out or become faulty over time. It's essential to periodically inspect them. Inadequate checks can lead to unanticipated failures. Understanding the limitations of MCBs is key. They may not trip in all overload scenarios. Awareness helps in making informed decisions.

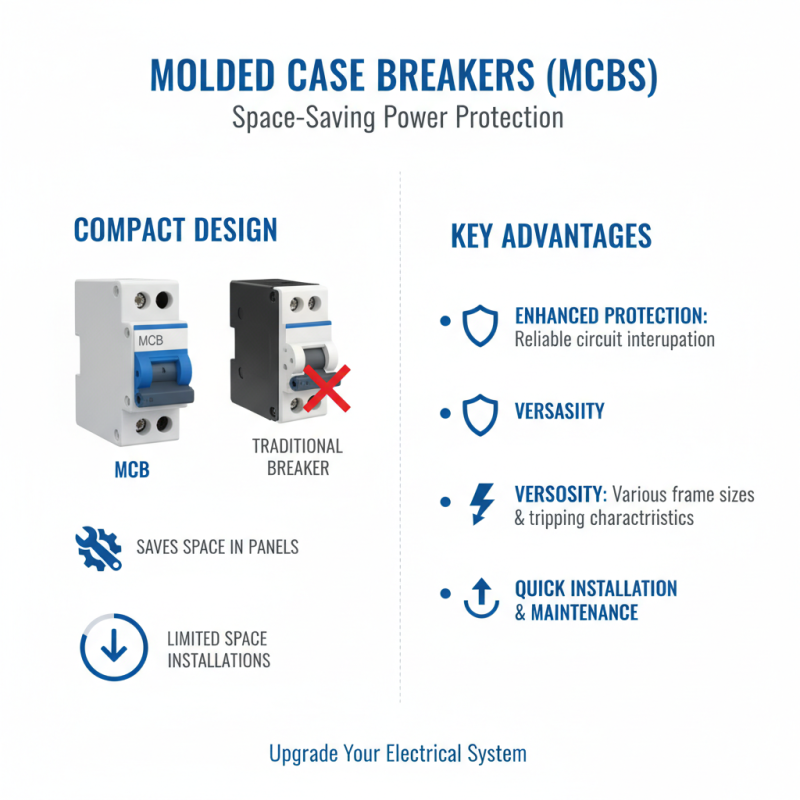

Advantages of Using Molded Case Breakers Over Other Breakers

Molded case breakers (MCB) are essential components in electrical systems. They offer unique advantages compared to traditional circuit breakers. One major benefit is their compact design. They save valuable space in control panels and cabinets. This is particularly important in installations with limited space.

Another advantage is their reliability. MCBs provide consistent performance under varied conditions. They are less prone to tripping due to voltage spikes. This reliability can reduce downtime. Users often experience fewer interruptions in operations. However, it's crucial to ensure proper sizing and settings. Incorrect adjustments may lead to nuisance tripping.

Additionally, MCBs feature advanced mechanisms for overload and short circuit prevention. They often include thermal and magnetic protection. This dual protection enhances safety. Some users may overlook this feature, leading to potential hazards. Proper education on MCBs is essential for effective use. Understanding their mechanisms can significantly improve overall safety.

Related Posts

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

-

Choosing Reliable Manufacturers: Essential Tips and Solutions for Best China Molded Case Circuit Breakers

-

Top 10 Things You Need to Know About Electric Main Breaker?

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

How to Choose the Right Molded Case Circuit Breaker for Your Electrical Needs

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500