7 Must-Know Tips to Maximize Efficiency with Air Breaker Circuit Breakers in Your Facility

In today’s competitive industrial landscape, optimizing energy efficiency is more crucial than ever, especially in facilities that rely heavily on electrical infrastructure. The implementation of Air Breaker Circuit Breakers (ABCBs) can significantly contribute to operational efficiency, given their ability to manage electrical loads effectively and reduce energy losses. According to a recent report by the International Energy Agency, energy efficiency improvements in industrial settings can lead to reductions in energy consumption by up to 25%. Moreover, the National Electrical Manufacturers Association highlights that the proper use of ABCBs not only enhances safety and reliability but also extends the lifespan of electrical equipment. Thus, understanding and maximizing the efficiency of Air Breaker Circuit Breakers is essential for facility managers looking to enhance their operational performance while minimizing costs and energy usage.

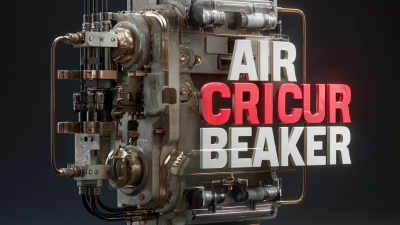

Understanding the Basics: How Air Breaker Circuit Breakers Work in Industrial Settings

Air circuit breakers (ACBs) play a crucial role in industrial settings, providing both protection and efficiency in power distribution. These devices operate by interrupting electrical flow during faults, thereby preventing damage to equipment and minimizing downtime. Understanding their function is essential for maximizing efficiency in any facility. ACBs use air as the arc-extinguishing medium, which allows them to handle high voltage applications effectively while offering lower maintenance compared to traditional breakers. This feature is particularly advantageous in large-scale operations where reliability is critical.

As the demand for electricity continues to rise globally, industries are increasingly turning to advanced circuit breakers that not only enhance safety but also contribute to sustainability goals. For instance, some modern ACB models integrate real-time monitoring capabilities, enabling facilities to track energy usage and identify inefficiencies. This shift towards smarter infrastructure is driven by the need for modernization and the integration of renewable energy sources. By investing in state-of-the-art air circuit breakers, facilities can not only ensure compliance with evolving electrical codes but also streamline operations, safeguard their assets, and support a transition to greener energy solutions.

Key Factors Impacting Efficiency: The Role of Quick-Trip Mechanisms in Air Breakers

The efficiency of air breaker circuit breakers is significantly influenced by the implementation of quick-trip mechanisms, which are essential for minimizing downtime and ensuring operational safety. According to a report from the Electric Power Research Institute (EPRI), facilities that utilized quick-trip mechanisms in their circuit breakers observed a 30% reduction in faults resulting from overload conditions. This efficiency translates not only to increased reliability but also to reduced maintenance costs and improved safety standards.

Moreover, quick-trip mechanisms work by rapidly detecting and isolating fault currents, allowing for an immediate response to electrical hazards. The National Electrical Manufacturers Association (NEMA) has noted that incorporating advanced trip settings can enhance the protection schemes in place, favoring a proactive approach to circuit management. Facilities that have adopted these technologies experienced a 25% improvement in operational efficiency, demonstrating that investing in quick-trip systems not only protects equipment but also optimizes energy use, leading to more sustainable operational practices.

Optimizing Maintenance Schedules: Industry Best Practices for Longevity of Circuit Breakers

To ensure the longevity of circuit breakers, it's essential to prioritize optimized maintenance schedules. Regular inspections can help identify wear and tear before they lead to major failures. This proactive approach not only extends the lifespan of your air breaker circuit breakers but also prevents unexpected downtimes that can disrupt operations. Scheduling maintenance during off-peak hours minimizes the impact on productivity while ensuring thorough evaluations by skilled technicians.

In addition to regular inspections, documenting maintenance activities is crucial. Keeping a well-maintained log allows you to track performance over time, identify recurring issues, and adjust maintenance strategies accordingly. Implementing predictive maintenance techniques, which utilize data analytics to forecast potential failures, can further enhance your facility's operational efficiency. By focusing on these industry best practices, you can significantly enhance the reliability and durability of your circuit breakers, ultimately leading to a safer and more efficient work environment.

7 Must-Know Tips to Maximize Efficiency with Air Breaker Circuit Breakers in Your Facility

| Tip | Description | Frequency of Maintenance | Expected Lifespan Extension |

|---|---|---|---|

| Regular Inspections | Perform visual and operational checks to identify potential issues early. | Monthly | 1-2 years |

| Clean Components | Remove dust and debris from circuit breakers to prevent overheating. | Quarterly | 6 months |

| Temperature Checks | Monitor operating temperature to ensure breakers are functioning within safe limits. | Monthly | 1 year |

| Test Trip Settings | Ensure that the trip settings function correctly to prevent overloads. | Annually | 2 years |

| Upgrade Aging Breakers | Replace old circuit breakers with modern models to enhance efficiency. | As Needed | 5-10 years |

| Document Maintenance | Keep a record of all maintenance activities for tracking and compliance. | Ongoing | N/A |

| Consult Professionals | Hire certified technicians for complex inspections and repairs. | Bi-Annually | 3-5 years |

Energy Savings Strategies: How Proper Sizing of Air Breakers Can Reduce Operational Costs

Proper sizing of air breaker circuit breakers is crucial for minimizing operational costs and maximizing energy efficiency in any facility. When air breakers are correctly sized to match the load requirements, they can help prevent energy losses that typically occur with oversized or undersized equipment. This alignment not only enhances the reliability of electrical systems but also contributes to substantial energy savings over time. Facilities can experience reduced demand charges and operational expenses when air breakers work optimally, demonstrating a straightforward yet effective strategy for cost reduction.

In addition, integrating advanced technologies can further improve the efficiency of air breakers. Automated systems that monitor energy consumption in real-time can help facility managers make data-driven decisions. By identifying patterns of usage and adjusting settings accordingly, organizations can enhance their energy management strategies, leading to sustainability goals being met more efficiently. As industries increasingly prioritize energy efficiency and decarbonization, employing well-optimized air breaker circuit breakers stands out as a pivotal approach to achieving these objectives while maintaining economic viability.

Integrating Technology: Leveraging Smart Monitoring Systems for Enhanced Circuit Breaker Performance

In today's rapidly evolving industrial landscape, the integration of smart monitoring systems has become essential for maximizing the performance of air breaker circuit breakers. These systems provide real-time data and analytics, enabling facility managers to proactively address potential issues before they escalate. By leveraging this technology, facilities can enhance their operational efficiency and reduce downtime significantly.

One effective tip is to implement predictive maintenance through smart monitoring. By analyzing historical data and identifying trends, facilities can schedule maintenance during non-peak hours, which minimizes disruption. Another crucial tip is to utilize smart alerts that notify staff about abnormal voltage levels or circuit interruptions, ensuring that any inefficiencies are immediately addressed. Additionally, integrating these systems with existing automation platforms can streamline overall facility management, ensuring that circuit breakers are functioning at optimal levels.

Smart monitoring also allows for enhanced decision-making through comprehensive reporting. With detailed insights on performance metrics, facility managers can make informed decisions regarding their equipment and necessary upgrades. Embracing these technologies not only boosts the efficiency of air breaker circuit breakers but also contributes to a safer and more reliable facility.

Related Posts

-

Revolutionizing Protection Standards for Low Voltage Circuit Breakers in 2030

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

-

The Future of Innovative Energy Management with Best Air Circuit Breakers

-

Exploring the Unique Features and Applications of Best Thermal Magnetic Circuit Breakers with Practical Usage Tips

-

Unlocking Energy Efficiency: The Advantages of Air Circuit Breakers for Global Industries

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500