The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

In today's rapidly evolving industrial landscape, the importance of reliable and efficient power distribution cannot be overstated. According to a report by MarketsandMarkets, the global market for electronic MCCBs (Molded Case Circuit Breakers) is expected to reach USD 5.4 billion by 2025, growing at a CAGR of 7.2%. This growth reflects the increasing demand for safety and efficiency in electrical systems across various sectors, including manufacturing, construction, and energy.

With their advanced features, such as digital monitoring and protection capabilities, electronic MCCBs are transforming the way industries manage electrical loads, reduce downtime, and enhance operational reliability. This ultimate guide will delve into the nuances of mastering electronic MCCBs for industrial applications, providing essential insights and practical strategies to optimize their use and ensure compliance with industry standards.

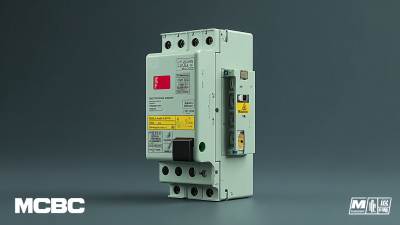

Understanding Electronic MCCB: Key Features and Benefits for Industrial Settings

In the realm of industrial applications, understanding the key features and benefits of electronic molded case circuit breakers (MCCBs) is essential for ensuring safety and operational efficiency. Electronic MCCBs are designed to provide a high level of protection against electrical faults while offering exceptional flexibility in a modular design. This adaptability is crucial in dynamic industrial environments where operational demands can rapidly change. According to market research, the MCCB market is projected to grow from approximately USD 4.22 billion in 2024 to an estimated USD 6.98 billion by 2033, highlighting the increasing reliance on advanced circuit protection solutions in various sectors.

Electronic MCCBs are equipped with advanced features such as adjustable settings for current ratings and integrated communication capabilities, allowing for real-time monitoring and data analysis. This level of sophistication not only enhances safety by reducing the risk of overloads and short circuits but also improves maintenance efficiency by facilitating prompt diagnostics. Furthermore, the modular nature of electronic MCCBs enables users to easily expand their systems with additional functions, affirming their role as a sustainable solution for the evolving needs of industrial facilities. As industries continue to embrace digital transformations, the adoption of electronic MCCBs will become increasingly vital to ensure both safety and operational flexibility.

The Performance of Electronic MCCB in Industrial Applications

This chart illustrates the key performance metrics of Electronic MCCBs in industrial settings. The metrics chosen provide insights into the response time, protection features, efficiency, cost, and lifespan of these devices, which are crucial for assessing their suitability for various industrial applications.

Comparative Analysis: Electronic MCCB vs. Traditional Circuit Breakers in Efficiency

In the evolving landscape of industrial applications, the efficiency of circuit protection devices is paramount. A comparative analysis between electronic MCCBs (Molded Case Circuit Breakers) and traditional circuit breakers reveals significant differences in operational effectiveness. Electronic MCCBs leverage advanced technology to provide superior fault detection, allowing for quicker response times and reduced downtime. This is particularly critical in large-scale setups, where the capacity to handle fault currents effectively can dictate the reliability of the entire electrical system.

To bolster the efficiency of your electrical systems, consider integrating electronic MCCBs, which typically feature adjustable trip settings and more precise overload protection. According to industry reports, electronic MCCBs can increase system reliability by up to 30% compared to their traditional counterparts. Additionally, they require less maintenance due to their enhanced diagnostics capabilities.

**Tips:** When selecting circuit protection, evaluate the specific needs of your application regarding fault handling and thermal performance. Regularly update your circuit protection strategy by analyzing operational data and adjusting settings to align with changes in load conditions. Lastly, invest in training personnel on the advantages of using electronic MCCBs to maximize safety and operational efficiency within your facility.

The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

| Feature | Electronic MCCB | Traditional Circuit Breaker |

|---|---|---|

| Response Time | Millisecond | Milliseconds to Seconds |

| Overload Protection | Digital Settings | Manual Settings |

| Reset Method | Remote or Automatic | Manual |

| Monitoring Features | Advanced (real-time) | Basic (none) |

| Energy Efficiency | High | Moderate |

| Cost | Higher Initial Investment | Lower Initial Investment |

| Maintenance Needs | Low | Higher |

Optimal Sizing and Selection Criteria for Electronic MCCB in Industrial Applications

When selecting electronic Molded Case Circuit Breakers (MCCBs) for industrial applications, it's crucial to consider optimal sizing and selection criteria to ensure safety and efficiency. Start by assessing the electrical load and application requirements. Understanding the peak demand and load characteristics will help you choose an MCCB that can handle the operational needs without risk of overloading.

Tips: Always refer to the manufacturer's specifications for current ratings and trip settings. Consider derating the MCCB for high ambient temperatures or continuous loads to enhance reliability. Additionally, ensure that the selected MCCB meets the protection needs specific to your industrial environment, including short-circuit, overload, and ground fault protection.

Another key aspect is environmental considerations. Different settings may require MCCBs that are resistant to dust, moisture, or corrosive elements. Selecting a suitable enclosure type can extend the lifecycle and performance of the MCCB.

Tips: It’s wise to consult with a professional to evaluate the potential environmental impacts on your MCCB and make necessary adjustments in the circuit breaker choice for maximum longevity and safety.

Integration of Smart Technology: Enhancing MCCB Functionality with IoT

In the realm of industrial applications, the integration of smart technologies into Molded Case Circuit Breakers (MCCBs) represents a significant leap forward. By embedding Internet of Things (IoT) capabilities within MCCBs, industries can gain unprecedented insights into their electrical systems. Real-time monitoring enables operators to track energy consumption, assess circuit conditions, and respond rapidly to potential overloads or faults. This proactive approach not only enhances safety but also boosts operational efficiency.

Moreover, the synergy of IoT and MCCBs opens doors to predictive maintenance strategies. With smart devices collecting data on usage patterns and performance metrics, facilities can anticipate equipment failures before they happen. This capability minimizes downtime and reduces maintenance costs, translating into substantial long-term savings. Additionally, integrating IoT with MCCBs facilitates remote management, allowing operators to control and adjust settings from anywhere, optimizing energy use and adapting to varying load conditions seamlessly.

As industries continue to evolve, the smart integration of technology with electrical components like MCCBs will be paramount in achieving operational excellence and sustainability.

Key Regulatory Standards and Compliance for Using Electronic MCCB in Industry

When utilizing electronic Molded Case Circuit Breakers (MCCBs) in industrial applications, adherence to key regulatory standards and compliance measures is essential. The International Electrotechnical Commission (IEC) sets the groundwork with standards like IEC 60947, which details the performance and safety requirements for electrical devices. Compliance with these standards ensures that electronic MCCBs can effectively manage overloads and short circuits, protecting both personnel and equipment. Understanding the nuances of these regulations helps industries mitigate risks associated with electrical failures.

In addition to IEC standards, various country-specific regulations may apply. For instance, in the United States, the National Electrical Code (NEC) governs the installation and operation of MCCBs, emphasizing the necessity of adhering to local jurisdictional requirements. Industries must also consider environmental standards, such as RoHS or WEEE, which ensure that electronic components are not harmful to the ecosystem. By being diligent in understanding and complying with these regulations, businesses not only safeguard their operations but also contribute to sustainable industrial practices.

Related Posts

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

Empowering the World with Chinese Excellence: The Unmatched Best Thermal Magnetic Release MCCB

-

Exploring the Spectrum: Real-World Applications and Innovations in Electrical MCCBs

-

10 Amazing Reasons Why Electronic MCCBs Are Essential for Your Business

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500