Understanding the Importance of MCCB: How Molded Case Circuit Breakers Ensure Electrical Safety

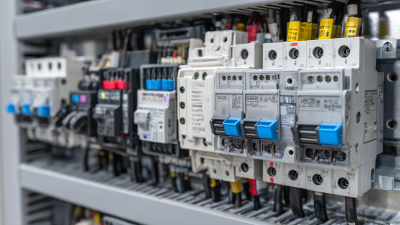

In today's rapidly advancing technological landscape, electrical safety is more crucial than ever,

making the understanding of MCCB Molded Case Circuit Breakers

indispensable for professionals and homeowners alike. These devices play a fundamental role in protecting electrical circuits from overloads and short circuits, ensuring that systems operate smoothly and safely.

As we delve into the intricacies of MCCB Molded Case Circuit Breakers, we will explore their functions, benefits, and the key reasons why they are essential components in modern electrical systems.

By recognizing the importance of these circuit breakers, we can better appreciate their role in preventing electrical hazards and enhancing overall safety in various environments, from residential settings to industrial applications.

This in-depth comprehension not only fosters a safer living and working space but also promotes proactive maintenance and informed decision-making

when it comes to electrical installations and upgrades.

In today's rapidly advancing technological landscape, electrical safety is more crucial than ever,

making the understanding of MCCB Molded Case Circuit Breakers

indispensable for professionals and homeowners alike. These devices play a fundamental role in protecting electrical circuits from overloads and short circuits, ensuring that systems operate smoothly and safely.

As we delve into the intricacies of MCCB Molded Case Circuit Breakers, we will explore their functions, benefits, and the key reasons why they are essential components in modern electrical systems.

By recognizing the importance of these circuit breakers, we can better appreciate their role in preventing electrical hazards and enhancing overall safety in various environments, from residential settings to industrial applications.

This in-depth comprehension not only fosters a safer living and working space but also promotes proactive maintenance and informed decision-making

when it comes to electrical installations and upgrades.

The Role of MCCB in Electrical Safety Management

Molded Case Circuit Breakers (MCCBs) play a crucial role in electrical safety management by providing reliable protection against overloads and short circuits. According to a report by the International Electrotechnical Commission (IEC), improper electrical installations contribute to nearly 30% of industrial electrical accidents. MCCBs help mitigate these risks by offering superior fault detection capabilities, ensuring that potential hazards are identified and addressed promptly.

When selecting MCCBs, it is essential to consider their ratings and features. A study from the National Fire Protection Association (NFPA) highlights that equipment designed with higher interrupting ratings can significantly reduce the risk of fire caused by electrical faults. This demonstrates the importance of utilizing appropriate MCCBs in safeguarding both personnel and property.

Tips:

- Regularly inspect and maintain your MCCBs to ensure they function correctly throughout their service life.

- Consider installing MCCBs with adjustable trip settings for tailored protection based on your specific electrical load requirements.

- Stay informed about advancements in MCCB technology, as newer models may offer enhanced safety features, improving your overall electrical management strategy.

Key Features and Benefits of Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) play a pivotal role in electrical safety by providing essential protection against overloads and short circuits. One of the key features of MCCBs is their ability to detect and interrupt excessive current flow. According to a report by Frost & Sullivan, the global MCCB market is expected to grow at a CAGR of 5.2% from 2022 to 2027, highlighting the increasing recognition of their benefits among industries. Their design allows for thermal and magnetic protection, ensuring that even in abnormal conditions, electrical systems remain safeguarded.

Another significant advantage of MCCBs is their versatility in various applications. They are available in a range of current ratings and can accommodate different voltage levels, making them suitable for both residential and industrial use. The National Electrical Manufacturers Association (NEMA) reports that MCCBs can have short-circuit interrupting ratings (ICR) of up to 200 kA, providing robust protection for sensitive electrical equipment. Furthermore, their compact size and user-friendly interfaces enhance installation efficiency and operational reliability, which is critical in today's energy-conscious environment. This combination of features ensures that MCCBs not only enhance safety but also contribute to the overall efficiency of electrical systems.

Steps to Select the Right MCCB for Your Electrical Needs

When selecting the right Molded Case Circuit Breaker (MCCB) for your electrical needs, several factors come into play. First and foremost, it's crucial to determine the current rating required for your specific application. This involves assessing the load calculations and ensuring that the MCCB can handle the maximum expected current without tripping unnecessarily. Additionally, the voltage rating should also align with your system’s specifications to provide adequate protection and functionality.

Another essential step is understanding the type of environment in which the MCCB will be installed. For instance, if it is to be placed in a location with higher humidity or potential exposure to dust and chemicals, choosing an MCCB with suitable ingress protection (IP) ratings is vital. Lastly, consider any additional features such as thermal-magnetic or electronic trip units based on the level of customization and precision your application demands. By focusing on these factors, you can ensure that your MCCB not only meets your electrical needs but also enhances overall safety and reliability in your electrical system.

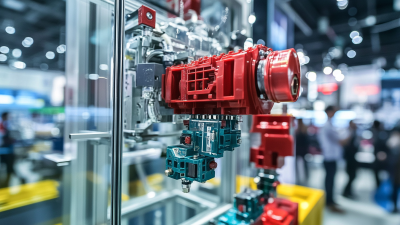

Common Applications of MCCBs in Various Industries

Molded Case Circuit Breakers (MCCBs) play a crucial role in a variety of industries by providing essential protection against overcurrents and short circuits. These devices are pivotal in sectors such as manufacturing, data centers, and commercial buildings where electrical loads can fluctuate significantly. According to a report by MarketsandMarkets, the global MCCB market size was valued at approximately $6.5 billion in 2021 and is projected to reach $8.2 billion by 2026, reflecting a growing demand for reliable electrical safety solutions across industries.

In manufacturing, MCCBs are utilized to safeguard machinery and electrical panels from overload conditions, allowing for uninterrupted operations and minimizing downtime. In data centers, they ensure the protection of sensitive equipment and infrastructure, which is critical for maintaining optimal performance and data integrity. Additionally, in commercial buildings, MCCBs provide circuit protection and help manage energy distribution efficiently. The National Electrical Manufacturers Association (NEMA) indicates that the integration of MCCBs in electrical systems can significantly reduce the risk of electrical fires, enhancing both safety and reliability for end-users.

Understanding the Importance of MCCB in Electrical Safety

Maintenance Tips for Maximizing MCCB Performance and Safety

Molded Case Circuit Breakers (MCCBs) are essential for maintaining electrical safety in modern infrastructure. According to industry reports, around 80% of electrical failures can be attributed to inadequate protective devices. Regular maintenance is crucial to ensure that MCCBs function optimally, as neglect can lead to increased downtime and potentially hazardous situations. Keeping these circuit breakers clean and free of debris, as well as tightening connections, can significantly extend their lifespan and improve performance.

One effective maintenance tip is to perform thermal imaging inspections. Studies show that thermal imaging can identify hot spots that indicate potential failure before they become critical, allowing for proactive interventions. Additionally, regularly testing the MCCBs for functionality is vital; isolated tests can ensure that they trip appropriately under fault conditions. By adhering to these practices, users can maximize the operational safety and performance of MCCBs, thereby safeguarding both personnel and equipment in various applications.

Related Posts

-

Understanding Common Issues Faced with Best MCCB Moulded Case Circuit Breakers

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500