Understanding the Importance of MCCB Moulded Case Circuit Breakers in Modern Electrical Systems

In today's increasingly complex electrical systems, the importance of MCCB Moulded Case Circuit Breakers cannot be overstated. These devices serve critical functions in protecting electrical circuits from overloads and short circuits, thereby ensuring the safety and reliability of modern infrastructure. According to a recent report by Markets and Markets, the global market for circuit breakers, which includes MCCB technologies, is projected to grow from USD 6.4 billion in 2020 to USD 8.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.4%. This surge highlights the rising demand for advanced protective solutions in various sectors, including construction, manufacturing, and energy distribution. As industries aim to enhance operational efficiency and safeguard their assets, understanding the role and functionality of MCCB Moulded Case Circuit Breakers becomes essential for engineers, technicians, and project managers alike.

The Role of MCCB in Enhancing Electrical Safety Standards

Moulded Case Circuit Breakers (MCCBs) play a crucial role in enhancing electrical safety standards within modern electrical systems. According to the National Fire Protection Association (NFPA), electrical failures account for nearly 13% of all reported structure fires in the United States, highlighting the urgent need for reliable protective devices like MCCBs. These circuit breakers are designed to detect overloads and short circuits, automatically disconnecting power to prevent potential hazards, thereby reducing the risk of electrical fires and equipment damage.

Additionally, the Global Electrical Circuit Breaker Market Report estimates that the demand for MCCBs is projected to grow at a CAGR of 5.4% from 2021 to 2028. This growth is driven by increasing regulatory requirements for safety and reliability in various sectors, including residential, commercial, and industrial applications. By ensuring compliance with international safety standards, such as IEC 60947-2, MCCBs enhance protection against electrical faults, contributing significantly to the overall safety framework of electrical installations. Their role extends beyond mere interruption of current; they are integral in safeguarding lives and property, reinforcing the importance of integrating advanced MCCB technologies in today's electrical systems.

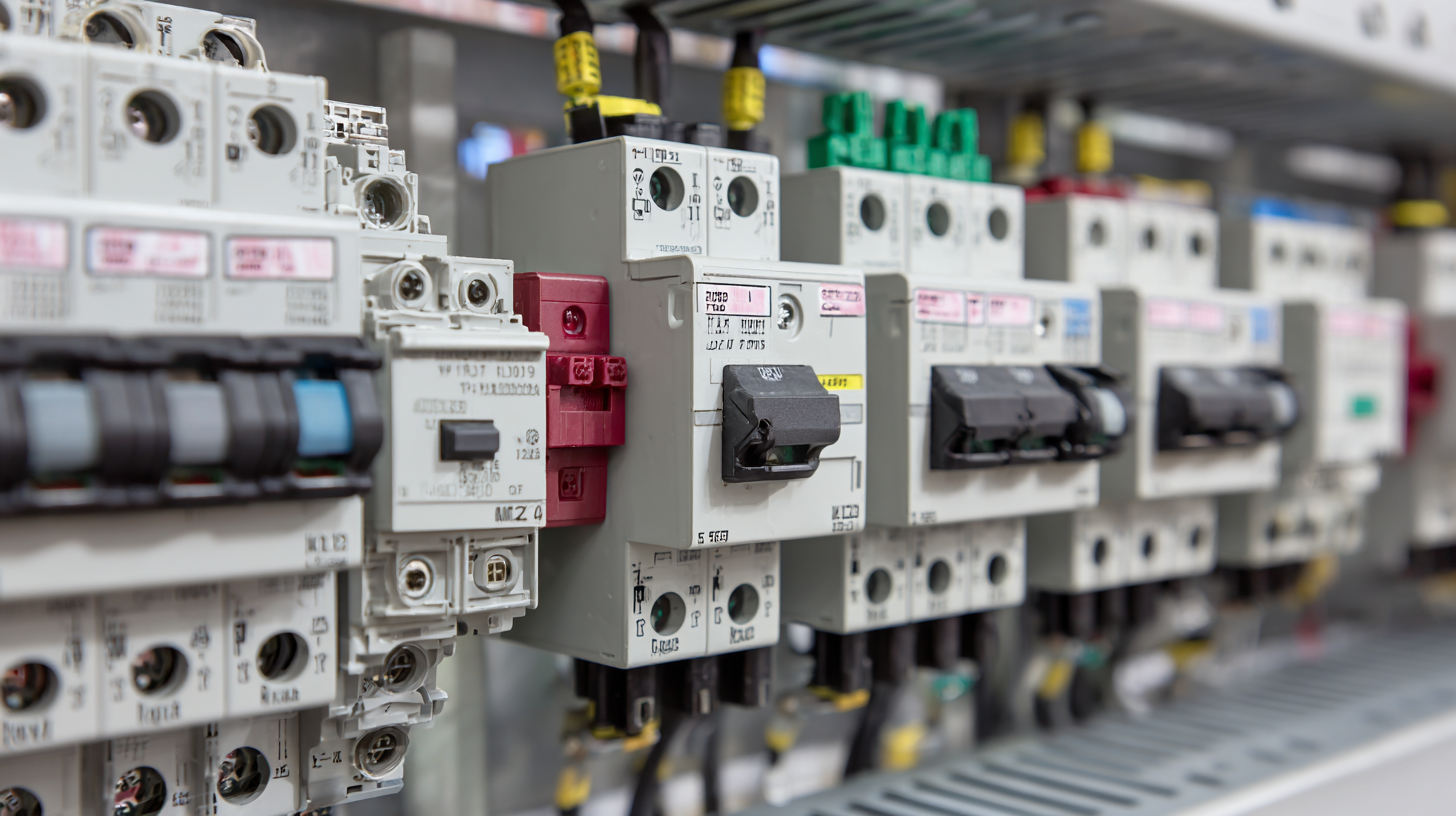

Key Features of MCCBs That Make Them Essential in Modern Systems

Moulded Case Circuit Breakers (MCCBs) play a pivotal role in the safety and efficiency of modern electrical systems. One of their key features is the ability to provide reliable overcurrent protection. This function safeguards electrical circuits from damage caused by excessive currents, which can result from short circuits or overloads. By automatically disconnecting the circuit under these hazardous conditions, MCCBs prevent potential equipment damage and reduce fire risks, making them indispensable in commercial and industrial settings.

Another essential feature of MCCBs is their thermal and magnetic trip mechanisms. The thermal trip responds to prolonged overload conditions, while the magnetic trip acts instantaneously during short circuits. This dual protection system ensures that electrical systems are shielded from both gradual and sudden faults. Additionally, MCCBs often come with adjustable settings that allow customization for specific applications, providing flexibility in system design. Their compact yet robust construction ensures they can handle high power levels while occupying minimal space, which is crucial in today's increasingly compact electrical installations.

Understanding the Importance of MCCB Moulded Case Circuit Breakers

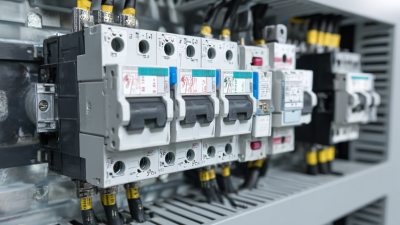

Comparative Analysis: MCCBs vs. Other Circuit Protection Devices

Moulded Case Circuit Breakers (MCCBs) are essential in modern electrical systems, particularly when comparing them with other circuit protection devices such as Miniature Circuit Breakers (MCBs) and residual current devices (RCDs). One significant advantage of MCCBs over MCBs is their capacity to handle larger current loads, making them suitable for industrial applications where higher amperage is a norm. Unlike MCBs, which are limited in their interruption capacities, MCCBs provide flexibility with adjustable settings that allow for a tailored protection approach, catering to specific requirements of various electrical systems.

Furthermore, while RCDs focus on preventing electrical shock by detecting earth faults, MCCBs offer comprehensive protection by addressing overloads and short circuits. This dual functionality makes MCCBs more versatile, ensuring that both equipment and personnel are safeguarded in numerous scenarios. In critical installations where downtime can have serious financial implications, the reliability and robustness of MCCBs provide a significant advantage, highlighting their role as a preferred choice for comprehensive circuit protection in modern electrical infrastructure.

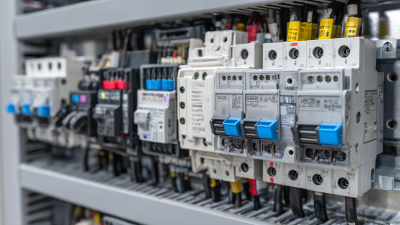

The Impact of MCCB Technology on Energy Efficiency in Electrical Networks

Molded Case Circuit Breakers (MCCBs) play a crucial role in enhancing energy efficiency within modern electrical networks. These devices not only serve as protective measures against overloads and short circuits but also contribute significantly to optimizing power consumption. By effectively managing electrical flow and maintaining an ideal operational environment, MCCBs help reduce unnecessary energy losses that often occur in less sophisticated systems.

The integration of advanced MCCB technology has led to improvements in load management and demand response capabilities. Many MCCBs are now equipped with smart features that allow for real-time monitoring and diagnostics, enabling more informed decision-making regarding energy use. This intelligence leads to better load balancing, as facilities can adjust their energy consumption patterns based on immediate demand, reducing peak loads and enhancing overall system efficiency. Consequently, the adoption of MCCBs not only ensures safety and reliability but also promotes sustainable energy practices in electrical networks.

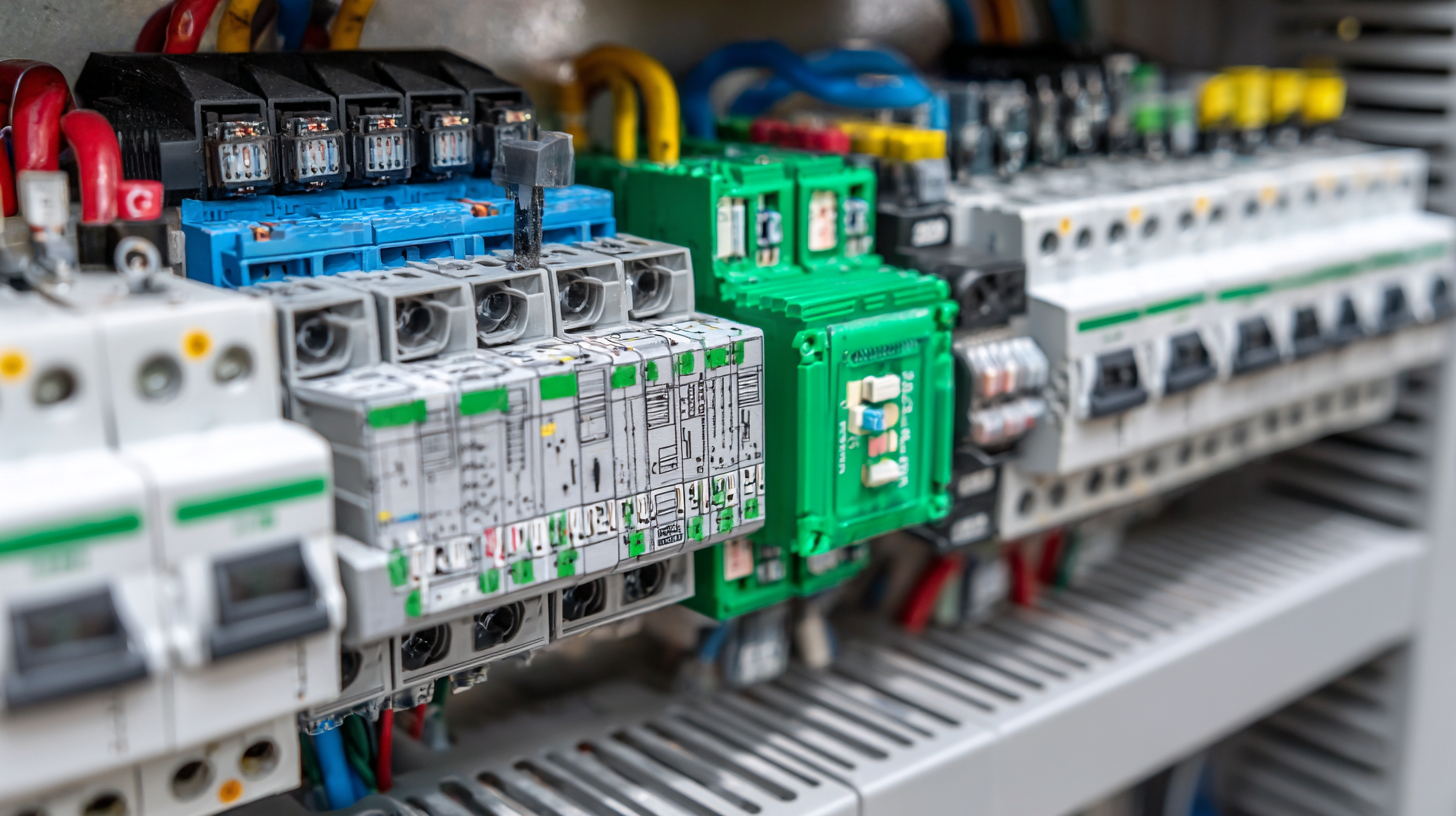

Challenges and Solutions in Implementing MCCBs in Industrial Settings

MCCBs, or moulded case circuit breakers, play a critical role in modern electrical systems, especially in industrial settings where safety and reliability are paramount. The implementation of MCCBs can face various challenges including space constraints, integration with existing infrastructure, and the need for advanced features to cater to evolving safety standards. Recent advancements in manufacturing, such as the establishment of local labs focused on new product introductions, highlight the industry's commitment to overcoming these obstacles.

For instance, the emergence of new circuit breaker platforms designed for digital industrial applications emphasizes rugged durability and advanced safety features, which are essential to meet the demands of harsh environments. These newer models often include options for remote monitoring and data collection, which facilitate proactive maintenance and enhance operational efficiency. As reported, the industrial sector is experiencing a significant shift, with estimates showing that the global market for circuit breakers could reach multi-billion dollar levels by 2025, driven by increasing automation and smart technology integration. Such trends underscore the necessity of addressing the challenges associated with MCCB implementation to ensure that industries can effectively harness the benefits of modern electrical systems.

Understanding the Importance of MCCB Moulded Case Circuit Breakers in Modern Electrical Systems - Challenges and Solutions in Implementing MCCBs in Industrial Settings

| Dimension | Details |

|---|---|

| Voltage Rating | Up to 1000V |

| Current Rating | Up to 6300A |

| Application Areas | Industrial, Commercial, Residential |

| Key Features | Short Circuit Protection, Overload Protection |

| Common Challenges | Installation Complexity, Maintenance Requirements |

| Solutions | Training, Simplified Installation Procedures |

| Regulatory Standards | IEC 60947-2, UL 489 |

Related Posts

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

Navigating Global Compliance: Import and Export Certifications for Best MCCB Moulded Case Circuit Breakers

-

How to Choose the Right Molded Case Circuit Breaker for Your Electrical Needs

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500