2025 How to Choose the Right MCCB (Moulded Case Circuit Breaker) for Your Electrical Needs

Choosing the right MCCB (Moulded Case Circuit Breaker) is essential for ensuring the safety and efficiency of your electrical systems. In the ever-evolving landscape of electrical applications, understanding the specifications and functionalities of different MCCB models can be daunting. This guide aims to simplify the selection process by providing crucial tips and insights, empowering you to make informed decisions tailored to your specific electrical needs.

As technological advancements continue to reshape how we manage electrical systems, the importance of selecting the correct MCCB cannot be overstated. A well-chosen MCCB not only protects your equipment from overloads and short circuits but also enhances the reliability of your entire electrical infrastructure. In this article, we will delve into key factors to consider when choosing an MCCB Moulded Case Circuit Breaker, including current ratings, interrupting capacity, and environmental considerations. Whether you are designing a new installation or upgrading an existing one, this guide will equip you with the knowledge needed to select the best MCCB for optimal performance and safety.

Understanding the Basics of MCCB: Functions and Applications

When selecting a Moulded Case Circuit Breaker (MCCB) for your electrical installations, it's crucial to understand its basic functions and applications. MCCBs serve as essential safety devices designed to protect electrical circuits from overcurrents, overloads, and short circuits. According to a report by MarketsandMarkets, the global MCCB market is projected to reach $7.6 billion by 2025, highlighting the increasing reliance on these devices in various industries, including residential, commercial, and industrial sectors.

MCCBs come with adjustable trip settings, allowing them to handle varying loads and ensuring optimal protection tailored to specific applications. They can manage circuit capacities ranging from 100A to 2500A, making them versatile for different electrical systems. For instance, in industrial settings where equipment is subject to high inrush currents, MCCBs can quickly disconnect the power to prevent damage, thereby improving operational efficiency and minimizing downtime. The International Electrotechnical Commission (IEC) has also provided guidelines on the appropriate selection of MCCBs, emphasizing the importance of considering factors like ambient temperature, humidity, and installation conditions to ensure reliable performance.

Key Factors to Consider When Selecting an MCCB for Your System

When selecting the right Moulded Case Circuit Breaker (MCCB) for your electrical system, several key factors must be considered to ensure optimal performance and safety. Firstly, one should assess the electrical characteristics of the application, such as the voltage rating and the current carrying capacity. According to a recent industry report by the International Electrotechnical Commission, 70% of electrical failures are attributed to incorrect device selection, highlighting the importance of aligning the MCCB with the specific needs of your system.

Another critical factor is the breaking capacity of the MCCB, which refers to its ability to interrupt fault currents. A study by the IEEE indicates that choosing an MCCB with inadequate breaking capacity can lead to catastrophic failures and downtime. Thus, it's essential to analyze the prospective fault currents in your system and select an MCCB with a breaking capacity that exceeds these levels, typically recommended to be at least 20% higher.

Tips: Always consult the manufacturer's specifications and consider factors like ambient temperature and installation conditions, as these can significantly affect the performance of the MCCB. Additionally, verify compliance with local standards and regulations to ensure safety and reliability in your electrical design.

Evaluating Voltage Ratings and Current Capacity for Your MCCB

When selecting the right MCCB (Moulded Case Circuit Breaker), evaluating voltage ratings and current capacity plays a crucial role in ensuring safe and efficient electrical system performance. According to the International Electrotechnical Commission (IEC) standards, MCCBs are available in various voltage ratings, typically ranging from 230V to 690V for industrial applications. Choosing the appropriate voltage rating is essential to prevent any insulation failure or operational hazards that may arise due to over-voltage conditions.

In terms of current capacity, it is vital to consider both the continuous and short-circuit rating of the MCCB. Current ratings usually range from 15A to 3,200A, depending on the applications and load requirements. A 2021 report from the National Electrical Manufacturers Association (NEMA) highlights that improper sizing of MCCBs can lead to functional inefficiencies and increased operational costs, emphasizing that a breaker should be rated adequately to handle peak loading conditions. Moreover, selecting the right MCCB not only ensures system reliability but also complies with relevant electrical safety standards, ultimately protecting both equipment and personnel in industrial setups.

Assessing Environmental Conditions for Optimal MCCB Performance

When selecting the right Moulded Case Circuit Breaker (MCCB) for your electrical system, assessing the environmental conditions is crucial. The operating environment significantly influences the performance and lifespan of an MCCB. Factors such as temperature, humidity, and the presence of dust or corrosive elements can impact the circuit breaker's effectiveness. For instance, extreme temperatures may lead to thermal stress, while high humidity can promote corrosion, affecting the connectivity and durability of components.

In addition, the installation location plays a pivotal role. MCCBs used in industrial settings may face exposure to vibrations and mechanical impacts, demanding units designed to withstand such conditions. Conversely, residential applications may prioritize aesthetics and quieter operation. By evaluating these environmental factors, you can choose an MCCB that not only meets your electrical needs but also ensures optimal performance and reliability, reducing the risk of malfunctions in adverse conditions.

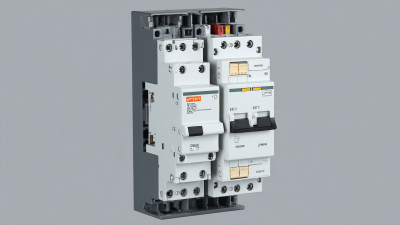

Comparing MCCB Features: Trip Settings, Accessories, and Standards

When selecting a Molded Case Circuit Breaker (MCCB), understanding the various features and their implications is crucial. One of the primary considerations is the trip settings. MCCBs typically offer several trip settings, including overload, short-circuit, and ground fault protection. According to the International Electrotechnical Commission (IEC), a well-chosen trip setting can minimize damage to electrical devices during faults and improve overall system reliability. For instance, setting the thermal trip correctly can prevent nuisance tripping while ensuring that true overload conditions are addressed effectively.

In addition to trip settings, the availability of accessories can enhance MCCB functionality. Common accessories include shunt trips, under-voltage releases, and auxiliary contacts, allowing for integration into a broader electrical control system. Research from the Electrical Research Institute indicates that utilizing these accessories can improve operational safety and efficiency by enabling remote shutdown capabilities and providing status feedback. Furthermore, compliance with standards like IEC 60947-2 ensures that the chosen MCCB meets rigorous safety and performance criteria, vital for maintaining operational integrity in various industrial environments. By comparing these features carefully, users can select an MCCB that precisely meets their specific electrical needs.

Comparison of MCCB Features for Electrical Needs

Related Posts

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

Exploring the Spectrum: Real-World Applications and Innovations in Electrical MCCBs

-

Understanding the Importance of MCCB Moulded Case Circuit Breakers in Modern Electrical Systems

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500