Ultimate Guide to Understanding Molded Case Breakers for Your Electrical Needs

In the realm of electrical distribution, the Molded Case Breaker (MCB) serves as a crucial component in protecting electrical circuits from overloads and short circuits. According to a comprehensive report by MarketsandMarkets, the global market for circuit breakers is projected to reach USD 13.28 billion by 2026, driven by increasing industrial automation and the growing need for energy-efficient systems. As electrical consumption continues to rise, understanding the intricacies of Molded Case Breakers becomes essential for both residential and commercial applications. This guide aims to demystify the functionality, advantages, and selection criteria for MCBs, empowering users to make informed decisions that enhance safety and efficiency in their electrical systems.

Understanding Molded Case Breakers: Definition and Functionality

Molded case breakers (MCBs) are essential components in modern electrical systems, designed to protect against overloads and short circuits. These devices combine the functionality of a switch and a circuit breaker, enabling efficient interruption of current flow in the event of an electrical fault. According to a report by Research and Markets, the global molded case circuit breaker market size is projected to reach $5 billion by 2026, emphasizing their critical role in ensuring electrical safety and efficiency in both residential and industrial applications.

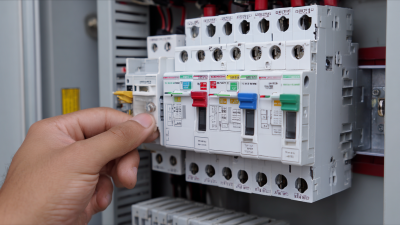

MCBs operate by using thermal and magnetic mechanisms to sense abnormal current flow. When an overload occurs, the thermal element responds to heat caused by excess current, while the magnetic mechanism reacts instantly to short circuits, providing dual protection. Users should ensure their MCBs are rated correctly for their application; selecting the right amperage according to the load is crucial for optimal performance.

**Tips:** Regular inspections of MCBs are essential to ensure they are functioning correctly. A recommended practice is to test the breakers monthly by resetting them to ensure they can trip under fault conditions. Additionally, understanding the tripping characteristics of MCBs helps in selecting the right type—B, C, or D types—based on the specific electrical load and application requirements.

Ultimate Guide to Understanding Molded Case Breakers for Your Electrical Needs

| Parameter | Description | Typical Values |

|---|---|---|

| Rated Current (In) | The maximum current the breaker can handle continuously. | 10A, 25A, 50A, 100A |

| Breaking Capacity (Icu) | The maximum fault current that the breaker can interrupt without being damaged. | 10kA, 25kA, 50kA |

| Trip Curve | The characteristic of the breaker that indicates how quickly it will trip at different current levels. | B, C, D |

| Mounting Type | How the breaker is designed to be installed in a panel. | Din Rail, Panel Mount |

| Poles | The number of circuits the breaker can protect. | 1P, 2P, 3P, 4P |

| Dimensions | Physical size of the breaker. | Length x Width x Height (mm) |

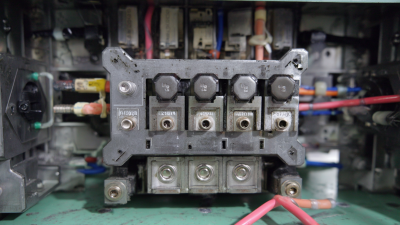

Key Components of Molded Case Circuit Breakers: A Detailed Breakdown

Molded case circuit breakers (MCCBs) are essential in modern electrical systems, providing overcurrent protection and reliable operation. Understanding the key components of these breakers can significantly impact their performance and lifespan. The primary components include the molded case, trip mechanism, and terminals. According to a recent report by Grand View Research, the MCCB market is expected to grow at a CAGR of 5.2% from 2021 to 2028, highlighting the increasing demand for efficient circuit protection in diverse industries.

The molded case serves as the foundation, housing the internal components while protecting them from environmental factors. Breakers utilize electromagnetic and thermal trip mechanisms to detect overcurrent conditions effectively. A study by MarketsandMarkets reveals that trip unit technologies, especially electronic trip units, are gaining popularity due to their enhanced accuracy and ability to provide adjustable settings. Lastly, the terminals are crucial for establishing secure connections with the electrical system. As the electrical landscape evolves, understanding these components will allow professionals to make informed decisions about MCCB implementation, ensuring safety and reliability in their electrical infrastructure.

Sizing Your Molded Case Breaker: Guidelines and Calculation Methods

When selecting a molded case breaker (MCB) for your electrical system, proper sizing is crucial to ensure safety and efficiency. According to the National Electric Manufacturers Association (NEMA), appropriate sizing can prevent potential overloads and short circuits, which represent about 30% of electrical failures in industrial settings. To size an MCB effectively, one must consider the continuous load, which should not exceed 80% of the breaker’s rated capacity. For instance, if an MCB is rated at 100A, the continuous load should be limited to 80A.

The calculation methods for sizing an MCB involve understanding key parameters such as the type of load, inrush current, and ambient temperature. The IEEE Standards Association recommends factoring in these elements to select a breaker that can handle surges without tripping unnecessarily. Industry reports suggest analyzing the load characteristics can improve performance by 15-20% while reducing the risk of equipment damage. Ensuring these guidelines are followed not only enhances the lifespan of electrical systems but also significantly boosts workplace safety standards.

Types of Molded Case Breakers: Choosing the Right One for Your Application

Choosing the right molded case breaker (MCCB) for your electrical needs is crucial for ensuring both safety and efficiency in your installations. There are several types of MCCBs available, each designed for specific applications. The primary factors to consider when selecting an MCCB include the maximum current rating, short-circuit protection capability, and additional features such as modular accessories. Industry reports indicate that the global MCCB market is expected to grow at a CAGR of over 4% from 2021 to 2026, reflecting the increasing demand for robust electrical protection solutions in commercial and industrial sectors.

When selecting the right type of molded case breaker, it's essential to understand the differences between standard and specialized breakers. Standard MCCBs are suitable for general applications, while specialized variants, equipped with advanced protection strategies, cater to more complex installations. For instance, some MCCBs are designed to integrate with residual current protective devices (RCDs), which can immediately cut off the current in fault conditions, enhancing safety. According to operational insights, one key consideration is the environment in which the MCCB will be used; factors such as humidity, temperature, and the presence of corrosive substances can significantly affect performance and longevity.

Preventive Maintenance for Molded Case Breakers: Best Practices and Tips

Preventive maintenance for molded case breakers (MCBs) is crucial to ensure the reliability and longevity of electrical systems. According to the National Fire Protection Association (NFPA), nearly 25% of electrical failures are attributed to a lack of maintenance. Implementing a regular maintenance schedule can significantly reduce these risks. Best practices include visual inspections, tightening connections, and testing the trip mechanisms. Regular thermal imaging can also help identify hotspots and potential failures before they escalate into major issues.

In addition to routine inspections, cleaning and lubrication of moving parts are essential. The Electrical Generating Systems Association (EGSA) recommends that breakers are cleaned to remove dust and debris at least once a year, particularly in industrial environments where contaminants are prevalent. Moreover, the annual testing of each breaker can forewarn facility managers about potential malfunctions, aligning with the Institute of Electrical and Electronics Engineers (IEEE) standards indicating that proactive maintenance can extend the functional lifespan of MCBs by up to 30%. By adhering to these preventive maintenance strategies, businesses can not only enhance safety but also optimize the performance of their electrical infrastructure.

Maintenance Factors for Molded Case Breakers

This bar chart illustrates the recommended maintenance frequency for molded case breakers (MCBs) based on best practices. Regular maintenance is essential to ensure optimal performance and reliability of electrical systems.

Related Posts

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

-

The Ultimate Guide to Understanding Air Breaker Circuit Breakers: Your Complete Resource

-

Unmatched Excellence in Manufacturing by Leading Chinese Factory for Best Electrical MCCB Solutions

-

Understanding Common Issues Faced with Best MCCB Moulded Case Circuit Breakers

-

The Ultimate Guide to Choosing the Right MCCB Adjustable for Your Electrical Needs

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500