Ultimate Guide to Selecting the Right Air Circuit Breaker for Your Industrial Needs

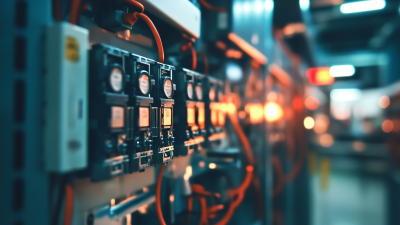

In today's industrial landscape, the need for reliable electrical protection systems is paramount, with air circuit breakers (ACBs) playing a crucial role in safeguarding equipment and personnel. According to a recent report by MarketsandMarkets, the global circuit breaker market is projected to reach USD 9.9 billion by 2026, driven by the increasing demand for renewable energy sources and the modernization of aging electrical infrastructure. As industries seek to enhance their operational efficiency and minimize downtime, selecting the right air circuit breaker becomes essential. Not only must organizations consider the specifications and ratings of these devices, but they must also align with the offerings from established Air Circuit Breaker Factory providers to ensure optimal performance and compliance with safety standards. This guide aims to navigate through the complexities of ACB selection, catering to diverse industrial needs while highlighting key factors that influence purchasing decisions.

Key Factors to Consider When Choosing an Air Circuit Breaker for Industrial Applications

When selecting an air circuit breaker (ACB) for industrial applications, several key factors must be considered to ensure optimal performance and safety. First and foremost, understanding the operational environment is crucial. Factors such as ambient temperature, humidity, and potential exposure to dust or corrosive substances can significantly impact the choice of an ACB. Breakers with higher IP ratings may be necessary in harsher conditions, providing the durability needed for long-term operation.

When selecting an air circuit breaker (ACB) for industrial applications, several key factors must be considered to ensure optimal performance and safety. First and foremost, understanding the operational environment is crucial. Factors such as ambient temperature, humidity, and potential exposure to dust or corrosive substances can significantly impact the choice of an ACB. Breakers with higher IP ratings may be necessary in harsher conditions, providing the durability needed for long-term operation.

Additionally, the load characteristics greatly influence the selection process. Assessing the type of loads—whether resistive, inductive, or capacitive—helps determine the appropriate ACB specifications, including its breaking capacity and tripping sensitivity. It is essential to choose a breaker that can handle both the load current and any potential short circuits without compromising safety. Furthermore, considering future expansion or modifications in the electrical system can save costs and effort down the line. By evaluating these factors carefully, you can select an air circuit breaker that meets both your current and future industrial needs effectively.

Types of Air Circuit Breakers and Their Specific Use Cases in Industries

When it comes to choosing the right air circuit breaker (ACB) for industrial applications, it’s essential to understand the various types available and their specific use cases. One popular type is the plain ACB, commonly used in power distribution systems where modulating electric currents is crucial for machine operation and safety. These breakers help in protecting electrical circuits from overloads and short circuits, making them a foundational component in manufacturing plants and large industrial setups.

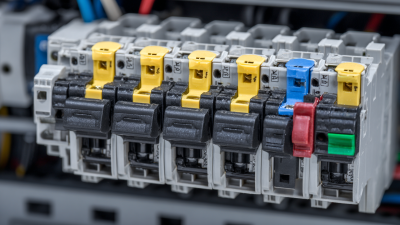

Another significant type of air circuit breaker is the intelligent ACB, which integrates advanced monitoring and control features. These breakers are equipped with digital relays that provide real-time data on power consumption and system performance, making them ideal for industries that prioritize energy efficiency and predictive maintenance. Sectors like pharmaceuticals and food processing particularly benefit from intelligent ACBs, as they help minimize downtime and maintain regulatory compliance through accurate usage tracking and alerts. Understanding these variations in air circuit breakers ensures that industrial facilities can enhance operational reliability and safety while adapting to the specific demands of their operations.

Understanding the Ratings and Specifications of Air Circuit Breakers

When selecting the right air circuit breaker (ACB) for industrial applications, understanding their ratings and specifications is crucial. Air circuit breakers are designed to provide protection against overloads and short circuits in electrical systems, ensuring safety and reliability. The global air circuit breaker market is projected to grow significantly, with a notable rise in demand driven by industries such as data centers and advanced manufacturing. By 2034, the market is expected to expand further, reflecting the increasing need for efficient energy management and resilient power solutions.

Low voltage air circuit breakers are particularly essential in various applications, as they dominate electrical power systems across industries. Recent advancements, such as the integration of smart technology in circuit breakers, enhance real-time energy tracking and boost safety measures. These innovations cater to a diverse range of sectors, highlighting the importance of selecting the right specifications for the specific demands of each application. The market is also witnessing the introduction of maintenance-free circuit breakers that utilize metal-graphene composites, promising improved durability and performance without compromising on safety standards.

Essential Safety Standards and Compliance Requirements for Air Circuit Breakers

When selecting the right air circuit breaker (ACB) for industrial applications, understanding essential safety standards and compliance requirements is crucial. Air circuit breakers must adhere to stringent safety regulations to ensure reliable operation and worker safety. According to industry analyses, the global market for air circuit breakers is projected to reach USD 12.9 billion by 2035, with a CAGR of 7.5% during the forecast period. This growth underscores the increasing emphasis on safety and compliance in industrial settings, where failure to meet standards can lead to significant risks.

Compliance standards often include IEC and UL specifications, which set forth requirements for performance, thermal stability, and protection against electrical faults. For instance, air circuit breakers must be capable of interrupting fault currents safely and efficiently. The SENTRON 3VA molded case circuit breakers exemplify innovations that enhance safety and adaptability in digital industrial environments. As industries continue to evolve, the importance of selecting ACBs that not only comply with but exceed these safety standards will remain paramount to ensuring operational integrity and regulatory adherence.

Air Circuit Breakers Selection - Compliance Standards Overview

Maintenance and Testing Checklist for Air Circuit Breakers to Ensure Reliability

When it comes to ensuring the reliability of air circuit breakers (ACBs) in industrial settings, a thorough maintenance and testing checklist is essential. Regular inspections should include verifying the functionality of the trip mechanism, ensuring that the connections are tight and free of corrosion, and checking the insulation resistance. By adhering to this checklist, facilities can prevent unexpected failures that could lead to costly downtime and safety hazards.

Moreover, aligning your ACB maintenance practices with standards like the Uptime Institute’s Tier III can significantly enhance the reliability of your electrical systems. Tier III certification requires a robust infrastructure with redundancy and fault tolerance, making it critical to maintain ACBs to meet these rigorous standards. Regular testing not only ensures compliance but also optimizes performance and prolongs the lifespan of critical electrical equipment, ultimately supporting operational efficiency and uptime in industrial applications.

Related Posts

-

Choosing Reliable Manufacturers: Essential Tips and Solutions for Best China Molded Case Circuit Breakers

-

Evaluating Air Circuit Breakers: Key Differences Between Leading Brands in 2023

-

Understanding Industry Standards and Challenges in Sourcing the Best Lsig Circuit Breaker Globally

-

The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

-

Exploring the Spectrum: Real-World Applications and Innovations in Electrical MCCBs

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500