Top 10 Essential Tips for Choosing Molded Case Circuit Breakers (MCCB)

Choosing the right Molded Case Circuit Breaker (MCCB) is crucial for ensuring the safety and efficiency of electrical systems across various industries. The global market for MCCBs is projected to reach USD 6.3 billion by 2025, reflecting a compound annual growth rate (CAGR) of 4.2% from 2018 to 2025, according to a report by MarketsandMarkets. This growth is driven by the increasing demand for energy-efficient solutions, as well as the heightened focus on the protection of electrical distribution systems from overloads and short circuits.

MCCBs provide versatile and reliable overload and short-circuit protection, making them essential components in industrial, commercial, and residential applications. According to the International Electrotechnical Commission (IEC), over 30% of electrical failures in industrial settings can be attributed to inadequate circuit protection. Therefore, understanding how to choose the appropriate MCCB is vital for reducing operational risks and ensuring compliance with safety standards. This article outlines the top ten essential tips for selecting Molded Case Circuit Breakers, which will empower electrical engineers and facility managers to make informed decisions when safeguarding their electrical systems.

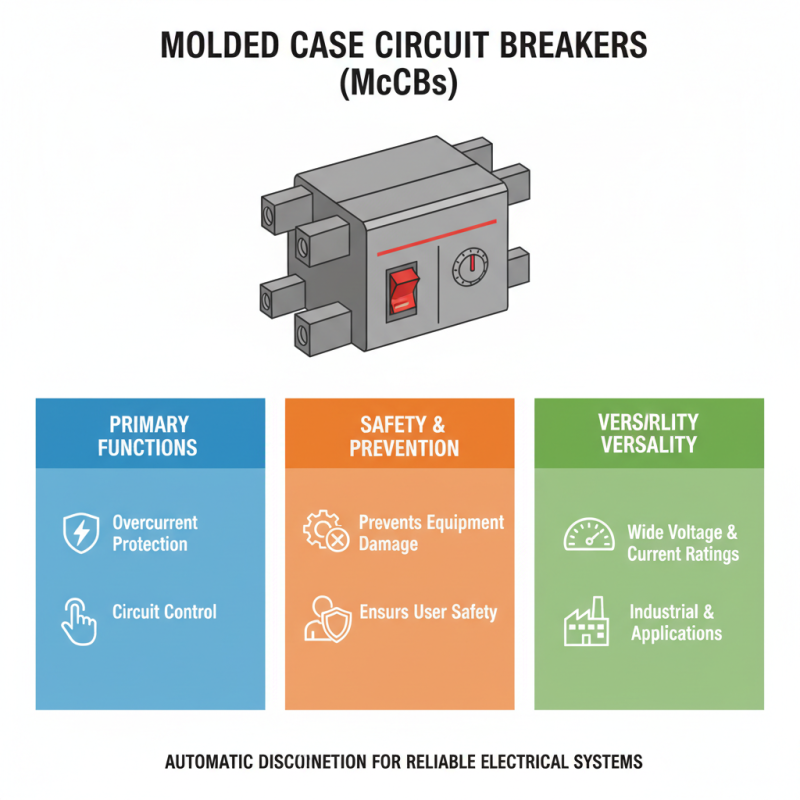

Understanding Molded Case Circuit Breakers (MCCB) and Their Functionality

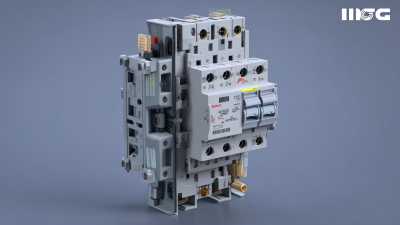

Molded Case Circuit Breakers (MCCB) play a crucial role in electrical systems by providing both overcurrent protection and control of electrical circuits. These devices are designed to automatically disconnect power in the event of overloading or short-circuiting, preventing damage to equipment and ensuring safety for users. The design of MCCBs allows them to handle a wide range of voltage and current ratings, making them versatile solutions for various industrial and commercial applications.

Understanding the functionality of MCCBs involves recognizing their key components, including the trip mechanism and the thermal-magnetic operation. The thermal aspect protects against overloads by using a bimetallic strip that bends and trips the circuit when excessive current flows. On the other hand, the magnetic component reacts quickly to short circuits, relying on an electromagnet that instantly triggers the mechanism to open the circuit. By grasping these fundamental principles, users can make informed decisions when selecting MCCBs tailored to their specific operational requirements, ultimately enhancing system reliability and safety.

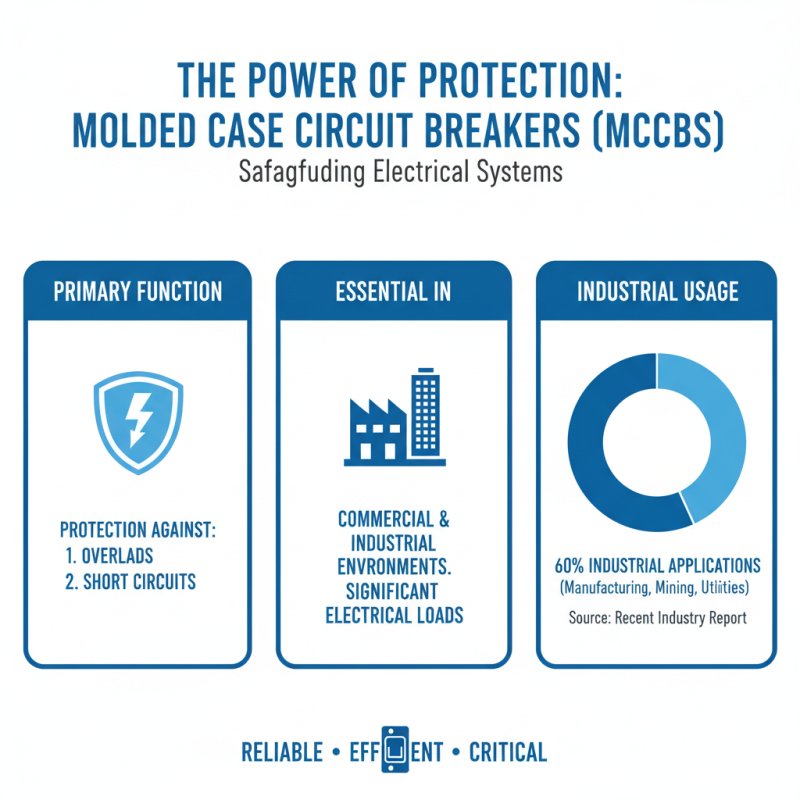

Identifying the Key Applications for Molded Case Circuit Breakers

Molded Case Circuit Breakers (MCCBs) play a vital role in electrical systems by protecting against overloads and short circuits. Their applications are diverse, but they are particularly essential in commercial and industrial environments where electrical loads are significant. According to a recent industry report, approximately 60% of MCCB usage is in industrial applications, highlighting their importance in manufacturing, mining, and utilities.

Understanding the key applications for MCCBs can significantly enhance the decision-making process when selecting the right circuit breaker. In environments with fluctuating loads, such as data centers and manufacturing plants, MCCBs are preferred for their ability to handle high fault currents and provide adjustable settings. Tips for choosing the right MCCB include assessing the specific electrical load requirements, evaluating environmental conditions, and determining the necessary breaking capacity.

Additionally, consider the regulatory standards applicable to your area; compliance is crucial for safety and efficiency. It's also beneficial to consult with industry professionals or utilize analytical tools to match MCCB features to specific applications. Engaging in a thorough analysis will lead to optimal safety and performance in critical electrical systems.

Evaluating the Ratings and Specifications of MCCBs

When selecting Molded Case Circuit Breakers (MCCBs), one of the critical factors to consider is the ratings and specifications that match your specific application requirements. According to the National Electrical Manufacturers Association (NEMA), MCCBs are designed to provide overload and short-circuit protection and must be chosen based on their continuous current ratings. A detailed evaluation of the rated current, breaking capacity, and trip settings is essential to ensure reliability and safety in your electrical systems.

Tip: Always opt for MCCBs with a breaking capacity that exceeds the maximum fault current expected in your application. This ensures that the circuit breaker will effectively handle short-circuit conditions without failure. It's recommended to check the latest IEC standards, which stipulate minimum breaking capacities based on application type, to guide your selection process.

Additionally, consider the specifications related to thermal and magnetic trip settings. Adjustability in settings can provide flexibility as load conditions change. Industry reports reveal that adjustable MCCBs can enhance operational efficiency, helping to minimize nuisance tripping while providing adequate protection.

Tip: Understanding the load characteristics, including inrush currents, can guide the proper set points for thermal and magnetic adjustments, ensuring optimal performance and longevity of your MCCB.

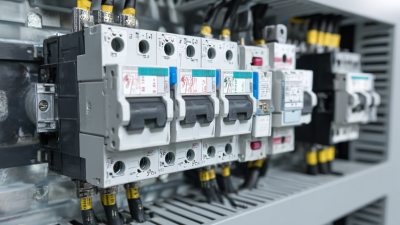

Factors to Consider for Installation and Maintenance of MCCBs

When choosing Molded Case Circuit Breakers (MCCBs), installation and maintenance are critical factors that can greatly affect their performance and longevity. According to a report by the International Electrotechnical Commission (IEC), improper installation can lead to a significant reduction in operational effectiveness, with failures accounting for approximately 25% of electrical system hazards. Ensuring that MCCBs are installed following the manufacturer's specifications and local electrical codes is essential. This involves selecting the appropriate size and type based on the electrical load, the environment, and potential fault levels.

Maintenance practices are equally vital for the extended life of MCCBs. According to the National Fire Protection Association (NFPA), routine maintenance checks should include thermal imaging, visual inspections, and functional testing. These preventive measures can help identify potential issues before they lead to substantial failures. Reports indicate that regular maintenance can enhance the reliability of electrical systems by up to 30%, significantly reducing downtime and repair costs. Moreover, a well-maintained MCCB can reliably operate under varying conditions, ensuring safety and efficiency in electrical installations.

Top 10 Essential Tips for Choosing Molded Case Circuit Breakers (MCCB)

| Tip | Description | Factors to Consider |

|---|---|---|

| 1. Determine the Load Requirements | Assess the total load to be connected to the MCCB to ensure it can handle the demand. | Load Capacity |

| 2. Identify the Voltage Rating | Choose an MCCB with a voltage rating that matches your electrical system. | Voltage Compatibility |

| 3. Consider the Current Rating | Select an MCCB with a current rating that matches or exceeds your application needs. | Current Rating |

| 4. Evaluate the Breaking Capacity | Ensure the MCCB can handle potential short circuit faults in your system. | Short Circuit Protection |

| 5. Check for Thermal Magnetic Protection | Choose MCCBs with thermal and magnetic trip settings for comprehensive protection. | Protection Type |

| 6. Review the Size and Space Requirements | Ensure the MCCB fits into the designated installation space. | Physical Dimensions |

| 7. Assess Environmental Conditions | Consider the installation location and environmental factors such as temperature and humidity. | Environmental Ratings |

| 8. Look for Industry Compliance and Standards | Ensure the MCCB meets relevant industry standards and certifications. | Compliance |

| 9. Consider Future Expansion | Select an MCCB that allows for future capacity increases in your electrical system. | Scalability |

| 10. Regular Maintenance Checks | Implement a schedule for routine maintenance to ensure longevity and proper functioning. | Maintenance Practices |

Comparing Different Brands and Models of Molded Case Circuit Breakers

When comparing different brands and models of molded case circuit breakers (MCCBs), it's essential to focus on specific characteristics that influence both performance and reliability. Key metrics such as interrupting capacity, which determines how much fault current the MCCB can safely interrupt without damage, should be scrutinized. Additionally, trip settings and mechanisms vary widely among models, affecting their response to overload and short-circuit conditions. Brands often differentiate themselves through enhanced features like thermal-magnetic trip units or electronic trip settings that provide customizable protection levels and greater accuracy.

Another important aspect to consider is the design and size of the MCCB. This can impact installation and integration into existing systems. Space constraints or specific environmental conditions may make certain models more suitable than others. Moreover, ease of maintenance, availability of replacement parts, and technical support should influence the decision-making process. Evaluating user reviews and industry ratings can also provide insights into long-term performance and reliability. By carefully analyzing these factors across multiple brands, you can make an informed choice that ensures both safety and efficiency in electrical systems.

Top 10 Essential Tips for Choosing Molded Case Circuit Breakers (MCCB)

Related Posts

-

How to Choose the Right Molded Case Circuit Breaker for Your Electrical Needs

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

Navigating Global Compliance: Import and Export Certifications for Best MCCB Moulded Case Circuit Breakers

-

Ultimate Guide to Understanding Molded Case Circuit Breakers for Global Procurement

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

7 Reasons Why the Best China Molded Case Circuit Breaker Is Essential for Your Business

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500