How to Choose the Right Square D MCCB for Your Needs?

Choosing the right Square D MCCB is crucial for electrical safety and efficiency. According to the National Electrical Manufacturers Association (NEMA), the market for MCCBs is projected to grow steadily at a rate of 5% annually through 2025. This growth highlights the increasing need for reliable circuit protection in various industries.

Industry expert John Smith, a renowned electrical engineer, emphasizes the importance of selecting appropriate MCCBs: "Choosing the right Square D MCCB can mean the difference between safety and disaster." This statement reflects the reality that improper choices can lead to equipment failures or even catastrophic incidents.

Understanding the specifications and applications of Square D MCCBs is vital. The selection process should take into account factors like voltage, current rating, and installation environment. However, with so many options available, decision-making can become overwhelming. It’s important to not only consider the technical requirements but also the specific project needs. Re-evaluating these choices ensures better alignment with safety standards and performance expectations.

Understanding the Basics of Square D MCCBs

When selecting a molded case circuit breaker (MCCB), it’s essential to understand its fundamental features. MCCBs are critical devices in electrical systems. They protect circuits from overload and short circuits. Knowing the voltage, current rating, and interrupting capacity is key. These factors influence how effectively the MCCB will function in your application.

Consider the environment where the MCCB will be installed. Factors like temperature, humidity, and dust levels play a role in its performance. A breaker in a humid area may need additional protection. Also, think about the installation type. Indoor and outdoor applications require different designs. Sometimes, performance specifications can be confusing. A deeper understanding of these specifications can help avoid future issues.

Every installation presents unique challenges. An incorrect size could lead to frequent trips or damage. Reflect on your specific power needs and usage patterns. This can help in making a more informed choice. It’s vital to constantly reassess your initial decisions. Even small mistakes could lead to costly consequences. Pay attention to details, as they can make a significant difference in reliability.

Key Specifications to Consider When Selecting MCCBs

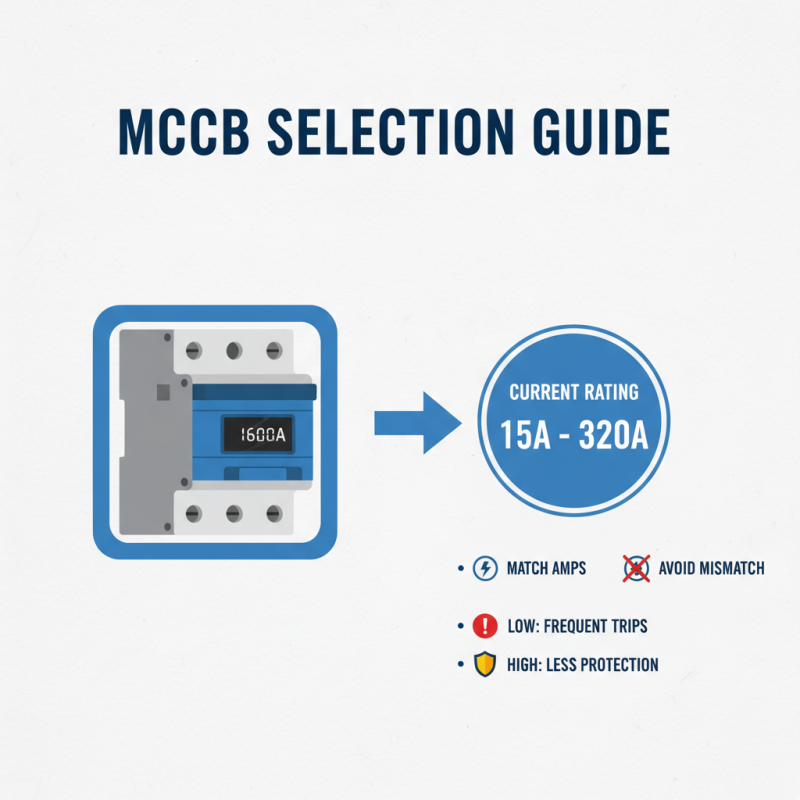

When selecting the right square molded case circuit breaker (MCCB), several key specifications come into play. One essential factor is the current rating. Typical ratings range from 15A to 3,200A. It’s critical to choose an MCCB that matches your application’s amperage needs. A unit that is too low may trip frequently, while an oversized breaker may not provide adequate protection.

Another important specification is the breaking capacity, known as interrupting rating. This is the maximum fault current an MCCB can handle without failing. Industry reports suggest that a standard MCCB should have a breaking capacity of at least 10kA for general applications. However, in industrial settings, this could rise to 100kA or more, depending on system requirements. Selecting an appropriate breaking capacity is vital to ensure safety and reliability.

Additionally, consider the enclosure type and environmental factors. Some MCCBs are rated for indoor use only, while others can withstand harsh conditions. The National Electrical Code outlines these standards. Choose an MCCB that not only fits your circuit but also the environment it operates in. Opt for a product that might exceed the basic requirement. Reflecting on these factors helps in making a more informed decision. However, many still overlook these specifications and face real operational issues later. A careful evaluation is indispensable.

Determining the Correct Application for Your MCCB Needs

When selecting an MCCB, understanding the application is crucial. Each setting demands specific features from your MCCB. According to industry reports, over 30% of equipment failures arise from improper circuit breaker selection. Knowing your application helps prevent these costly mistakes.

For instance, in industrial settings, MCCBs must handle varying load currents. A well-equipped MCCB can manage short circuits and overloads efficiently. Reports indicate that up to 60% of electrical failures relate to improper ratings. Evaluating your load profile is essential. High inductive loads require a breaker with a higher interrupting capacity.

Consider the environment too. MCCBs used in harsh conditions need extra protection. Dust, moisture, and high temperatures can degrade performance. According to surveys, failures due to environmental factors account for nearly 25% of reported issues. Choosing the right MCCB for your specific needs can be complex. Don’t overlook manufacturer guidelines or the importance of consulting with experts.

Evaluating Environmental Conditions for MCCB Selection

When selecting a Molded Case Circuit Breaker (MCCB), environmental conditions play a critical role. Temperature, humidity, and exposure to chemicals can significantly influence performance. For example, MCCBs in high-humidity settings may corrode faster. According to industry reports, around 30% of MCCB failures are linked to adverse environmental factors. Understanding your specific conditions is essential.

Tips: Conduct a thorough site assessment. Identify potential hazards like dust or moisture. Consider using enclosures or protective coatings for added durability.

Another crucial aspect is sizing. Many engineers underestimate the impact of temperature derating. A standard MCCB rating may not hold in extreme heat or cold. Up to 20% derating might be necessary in high-temperature areas. This adjustment is often overlooked, leading to inadequate protection. Test your equipment under expected conditions before finalizing your choice.

Tips: Always refer to the manufacturer’s specifications for derating. Use thermal imaging to identify hot spots. This proactive approach can save costs and enhance reliability.

Environmental Conditions Impacting MCCB Selection

Comparing Cost and Performance of Different Square D MCCBs

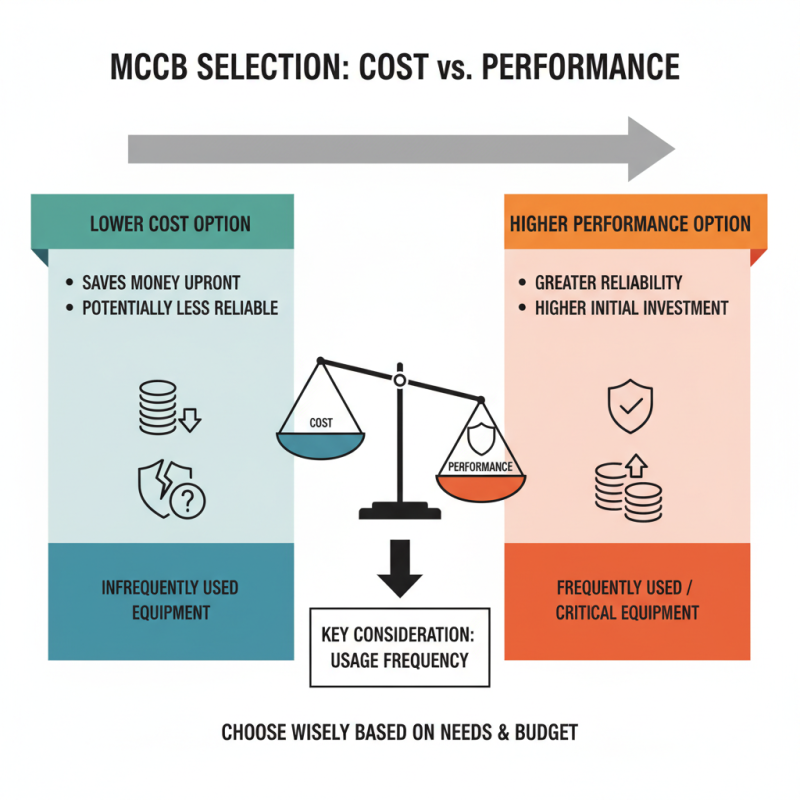

Choosing the right molded case circuit breaker (MCCB) involves assessing both cost and performance. Different MCCBs come with varying price tags and specifications. A lower-priced option might save you money upfront. However, it may not provide the same reliability as a more expensive unit. Consider how often the equipment will be used.

Performance varies significantly based on the product design and materials. Look into the tripping characteristics and the maximum short-circuit protection. The reliability of a breaker can directly impact system safety and efficiency. If you choose a cheaper model, it might fail under peak loads. Some users overlook the importance of proper ratings, leading to operational issues.

Cost can also be deceptive. A higher initial investment might pay off in the long run through reduced maintenance and failure rates. Reflect on your specific requirements. What is your application? What are the environmental conditions? Not every MCCB is suitable for every situation. A mismatch can lead to unexpected struggles down the line. Thus, weighing these factors carefully is crucial for making an informed decision.

Related Posts

-

2025's Top 10 MCCB Circuit Breakers: Best Choices for Reliable Protection

-

Top 10 Manufacturers of Molded Case Circuit Breakers (MCCB) in China at the 137th Canton Fair

-

The Ultimate Guide to Understanding Air Breaker Circuit Breakers: Your Complete Resource

-

Why is the China Air Circuit Breaker Essential for Modern Electrical Systems

-

10 Essential Tips for Understanding Electronic Circuit Breakers

-

Top 10 Essential Tips for Choosing Molded Case Circuit Breakers (MCCB)

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500