How to Choose the Right Microprocessor Based MCCB for Your Needs

When selecting a Microprocessor Based MCCB, various factors come into play. Understanding these elements is crucial for a proper fit to your needs. A Microprocessor Based MCCB offers advanced features, enhancing protection and control. These devices are not one-size-fits-all; the right choice depends on specific requirements.

Consider the application where the MCCB will be used. Will it protect sensitive equipment or manage heavy loads? This decision shapes your choice significantly. Also, think about the environmental conditions. Temperature and humidity can affect device performance, so understanding your settings is vital.

Testing different models can reveal unexpected challenges. You might find that a model with high specifications does not suit your environment. Reflection on your needs will guide you to a more effective solution. Remember, the goal is to find a balance between safety and functionality with your Microprocessor Based MCCB.

Understanding the Basics of Microprocessor-Based MCCBs

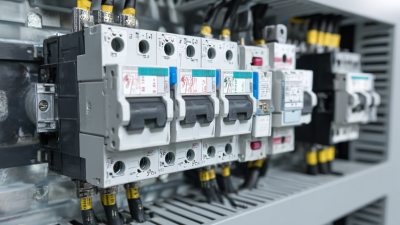

Microprocessor-based moulded case circuit breakers (MCCBs) are essential for modern electrical systems. They offer advanced protection features that enhance reliability. These breakers can monitor electrical parameters, detect faults, and provide trip settings. Their ability to adapt to various load conditions sets them apart from traditional options.

Understanding the basics of microprocessor-based MCCBs is crucial for making informed choices. These devices use digital technology to analyze current flow. This allows for quicker response times during fault conditions. Features like programmable settings can cater to specific needs. However, users must be cautious about the complexity of settings. A slight misconfiguration can lead to inadequate protection. Regular reviews of settings are necessary to ensure optimal performance.

Installation and maintenance are also key areas to consider. While the technology is advanced, proper calibration is required to avoid issues. Users sometimes overlook the importance of routine checks. Familiarizing oneself with the manual can help in troubleshooting. Recognizing the limits of the technology is vital. Even the best systems can fail if not used correctly. Seeking expert advice when in doubt can avoid costly mistakes.

Key Features to Consider When Choosing an MCCB

Selecting the right microprocessor-based MCCB can be daunting. Key features should guide your decision. Look at the insulation resistance. This should exceed 1 MΩ under normal conditions. A good report indicates that breakdowns often occur below this threshold. Consider the interrupting capacity as well; it should match the potential fault currents in your application.

Reliability is another essential feature. The MCCB must operate consistently under various environmental conditions. A recent industry study revealed that 30% of equipment failures are due to poor circuit protection. Pay attention to the thermal and magnetic trip settings. Customizing them will enhance operational efficiency.

Tips: Always review technical specifications carefully. Misunderstanding these can lead to serious issues. Look for user reviews on performance. Real-world feedback often highlights design flaws. Ensure you understand the installation requirements fully. Missteps in installation can lead to critical failures, impacting productivity and safety.

Evaluating Your Electrical System’s Requirements

When selecting a microprocessor-based MCCB, it's crucial to know your electrical system’s needs. Start by assessing the load requirements. This involves determining the total current load your system will operate under. A clear understanding allows for the selection of an MCCB that can handle peak demands without tripping unnecessarily.

Consider the environment as well. Is the installation indoors or outdoors? Will it be exposed to dust, moisture, or extreme temperatures? Each condition might affect the performance of the MCCB. For instance, a dusty environment can lead to overheating. Think about future expansion too. Systems often grow, and an undersized MCCB today may not suffice tomorrow.

However, understanding these details can be complex. You might find conflicting information or unclear specifications. It’s easy to overlook something crucial. Engage with professionals if needed, as they can clarify aspects you might miss. After all, implementing the right MCCB not only protects your system but also enhances its overall efficiency.

How to Choose the Right Microprocessor Based MCCB for Your Needs

| Criteria | Description | Example Values |

|---|---|---|

| Voltage Rating | The maximum voltage the MCCB can safely handle. | 230V, 400V, 690V |

| Current Rating | The load current the MCCB can interrupt. | 10A, 25A, 63A, 100A |

| Breaking Capacity | The maximum fault current the MCCB can interrupt without failing. | 6kA, 10kA, 25kA |

| Number of Poles | Defines how many circuits the MCCB can protect. | 1-Pole, 2-Pole, 3-Pole, 4-Pole |

| Type of Protection | Indicates if protection is thermal, magnetic, or both. | Thermal Magnetic, Electronic |

| Installation Type | Specifies how the MCCB can be installed. | Panel Mount, Surface Mount |

Comparing Leading Microprocessor-Based MCCB Brands

When selecting a microprocessor-based MCCB, understanding different brands can be insightful. Many leading manufacturers offer innovative features. Comparing their offerings helps identify the best fit for your specific requirements. Pay attention to the protective functions they provide. Some brands excel in overload protection, while others focus on short-circuit protection. This distinction can greatly impact performance under different conditions.

Installation and user interface are crucial aspects. Some brands have more intuitive controls. This can simplify training for your team. Look for options with clear indicators and detailed documentation. However, not all brands excel in customer support. A lack of proper guidance can lead to installation headaches. Researching user reviews can be beneficial.

It's essential to consider your unique needs. Each application may require different settings or configurations. Overlooking these specifics can result in subpar protection. Always ensure that the MCCB chosen aligns with your operational parameters. Reflect on past experiences as well; they can guide you in making better choices. Identifying the right brand involves acknowledging imperfections in each option. Take your time to weigh these factors carefully.

Comparison of Microprocessor-Based MCCB Features

Installation and Maintenance Tips for Optimal Performance

When installing a microprocessor-based MCCB, proper placement is crucial. Choose a location that is dry and accessible. Avoid areas with high humidity or excessive heat. The environment can impact performance. Always follow the manufacturer's guidelines while installing. This ensures safe operations and longevity.

Maintenance is key to optimal performance. Regularly inspect connections and the housing for any signs of wear. Dust and debris can accumulate, leading to overheating. Be mindful of this. Cleaning should be done carefully, using appropriate tools.

Here are a few tips: Schedule routine checks, ideally every six months. Test the MCCB under loaded conditions to ensure it trips as expected. Monitor for unusual sounds or smells. Act quickly if you notice any irregularities. Trust your instincts; if it feels off, investigate further. Each detail matters to maintain effectiveness.

Related Posts

-

Empowering the World with Chinese Excellence: The Unmatched Best Thermal Magnetic Release MCCB

-

Exploring Unique Alternatives to the Best Low Voltage Circuit Breaker for Your Electrical Needs

-

Revolutionizing Protection Standards for Low Voltage Circuit Breakers in 2030

-

Ultimate Techniques for Selecting the Best Molded Case Breaker in Today’s Market

-

Navigating Global Compliance: Import and Export Certifications for Best MCCB Moulded Case Circuit Breakers

-

Exploring Future Trends in After Sales Support and Repair Costs for Best Molded Case Breakers

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500