How to Choose the Right Air Circuit Breaker for Your Electrical System

Choosing the right Air Circuit Breaker (ACB) is crucial for ensuring the reliability and safety of electrical systems. According to a report by the International Electrotechnical Commission (IEC), approximately 70% of electrical failures are attributed to inadequate protection methods. The global ACB market is projected to reach USD 2.3 billion by 2025, driven by increasing demand for enhanced electrical safety and efficiency in various sectors, including industrial, commercial, and residential applications.

An appropriately selected ACB not only protects against overcurrents and short circuits but also optimizes the power distribution process, thereby minimizing downtime and potential damage to equipment. With a variety of specifications and types available, understanding the fundamental criteria for selecting an ACB tailored to your specific electrical system is essential for both performance and compliance with industry standards.

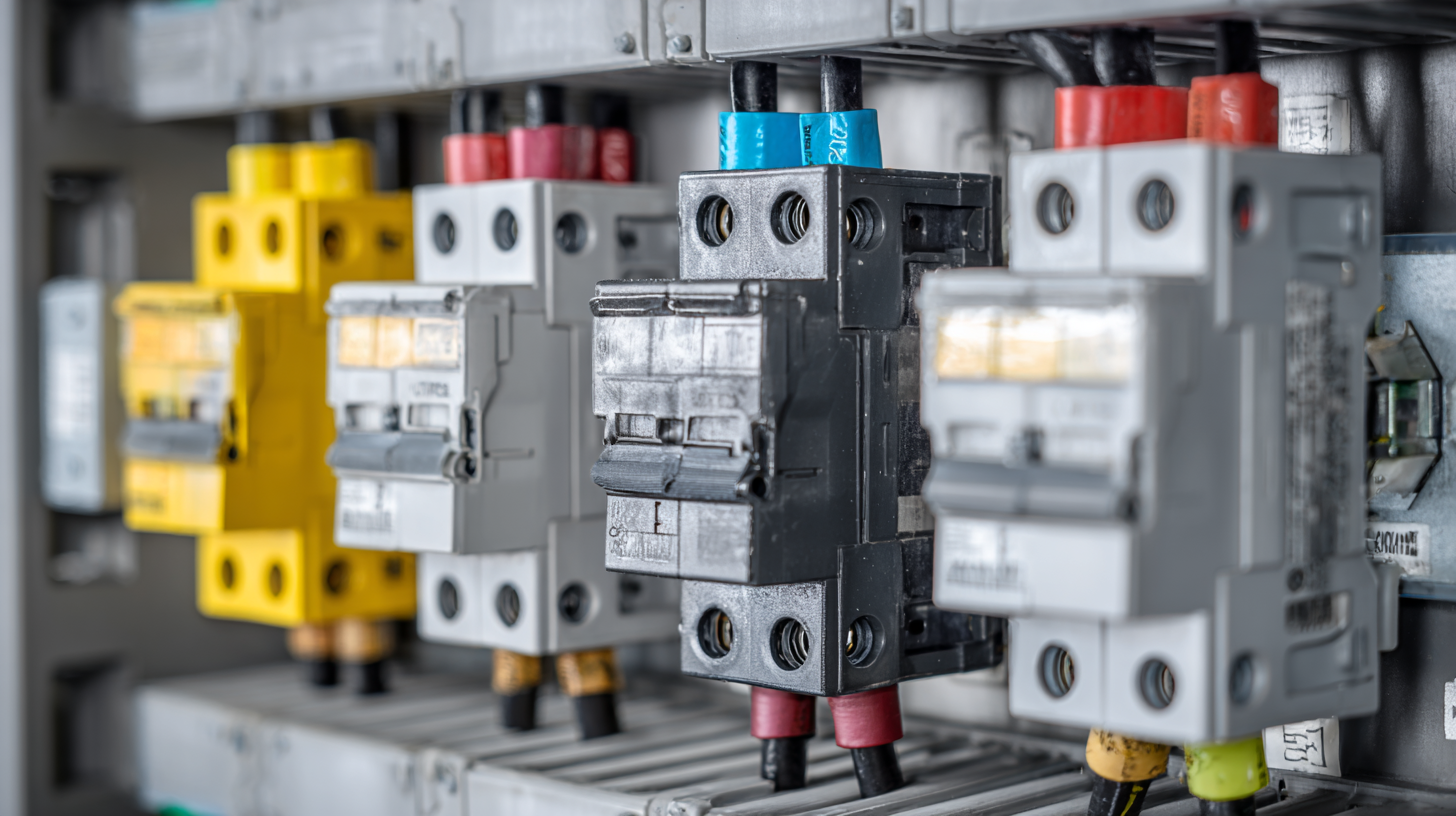

Understanding the Functionality of Air Circuit Breakers in Electrical Systems

Air circuit breakers (ACBs) play a crucial role in electrical systems by providing overcurrent protection, short-circuit protection, and the ability to interrupt excessive currents safely. Understanding their functionality involves knowing their operational principles, types, and applications in various setups, from low-voltage networks to industrial settings. The technology embedded in modern ACBs allows for enhanced safety features and real-time monitoring capabilities, making them more adaptable to today's digital industrial requirements.

When selecting an ACB, consider the specific needs of your electrical system. Here are some tips to guide your choice:

1. **Assess Load Requirements**: Ensure the ACB can handle the maximum load of your system while providing necessary safety margins.

2. **Evaluate Environmental Conditions**: Choose ACBs designed to withstand your operating environment, especially in industrial applications where durability is key.

3. **Look for Smart Features**: Opt for ACBs that offer real-time monitoring and data analysis capabilities to enhance operational efficiency and safety.

These considerations will help optimize the performance and longevity of your electrical system while ensuring safety and compliance with industry standards.

How to Choose the Right Air Circuit Breaker for Your Electrical System

| Criteria | Description | Importance Rating (1-5) |

|---|---|---|

| Current Rating | Must match the maximum load your system can handle. | 5 |

| Voltage Rating | Should be compatible with the operating voltage of your system. | 5 |

| Breaking Capacity | Ability to interrupt fault currents without failure. | 5 |

| Type of Operation | Manual or automatic operation based on application needs. | 4 |

| Protection Features | Additional features including ground fault, overload, and short circuit protection. | 5 |

| Environmental Conditions | Considerations for temperature, humidity, and dust levels. | 3 |

| Size and Mounting Options | Ensure compatibility with your installation space. | 4 |

Key Factors to Consider When Selecting an Air Circuit Breaker

When selecting the right air circuit breaker (ACB) for your electrical system, several key factors must be considered to ensure optimal performance and safety. One of the primary aspects is the interrupting capacity of the ACB, which is the maximum fault current it can safely interrupt without failing. This capacity should be assessed based on the potential fault levels in your system. Additionally, it is imperative to evaluate the ACB's voltage rating, which must align with your electrical system's voltage to prevent operational failures.

Another important factor is the ACB's operational characteristics, including its tripping mechanism. Understanding the different trip settings—such as thermal and magnetic—can help determine how the ACB will respond to overloads and short circuits. Moreover, consider the environmental conditions where the ACB will be installed, as factors such as humidity, temperature, and dust can affect its performance. Selecting an ACB designed for the specific setting can significantly enhance its reliability and longevity, ensuring your electrical system remains safe and efficient.

Evaluating the Current and Voltage Ratings for Optimal Performance

When selecting the right air circuit breaker (ACB) for your electrical system, evaluating current and voltage ratings is crucial for ensuring optimal performance. The current rating indicates the maximum continuous current the circuit breaker can handle without tripping, while the voltage rating determines the highest voltage that the device can safely interrupt. According to industry data from the National Electrical Manufacturers Association (NEMA), improper ratings can lead to severe system failures, resulting in costly downtime or even safety hazards.

Tips: Always refer to the specific requirements of your electrical load and system configuration. For instance, a facility with heavy machinery should consider ACBs with higher current ratings to accommodate short-term current surges. Additionally, it’s recommended to select breakers that exceed your calculated load requirements by at least 25% to provide a safety margin.

Moreover, accurate calculations of short-circuit currents are essential, as they help in selecting ACBs that can effectively manage fault conditions. Reports suggest that up to 30% of electrical failures in industrial applications can be linked to inadequate circuit protection. Therefore, it's advisable to consult with a qualified electrical engineer to determine the appropriate ratings tailored to your system's needs.

Assessing Environmental Conditions and Their Impact on Breaker Selection

When selecting the right air circuit breaker (ACB) for your electrical system, it is crucial to assess the environmental conditions that may impact the breaker’s performance and longevity. Factors such as temperature, humidity, and exposure to pollutants can significantly influence the operational reliability of the ACB. For instance, according to a report by the International Electrotechnical Commission, circuit breakers operating in high-humidity environments may require additional moisture protection features to avoid premature failure and increase longevity.

Furthermore, the integration of climate considerations into electrical infrastructure is more pressing than ever. A recent methodology resource aimed at enhancing the resilience of power networks emphasizes the importance of climate-proofing electricity distribution systems. This approach underlines the need for ACBs that can withstand fluctuating environmental conditions resulting from climate change. For example, more frequent and intense hydrologic events demand breakers that not only meet standard operational criteria but also demonstrate enhanced performance under stress conditions induced by extreme weather. By choosing the right ACB with these environmental factors in mind, you can ensure a reliable and efficient electrical system that is resilient to changing conditions.

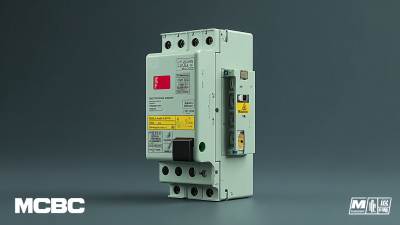

Comparing Different Manufacturers and Their Product Offerings

When selecting an air circuit breaker (ACB) for your electrical system, comparing different manufacturers is essential to ensure optimal performance and reliability. According to a report by MarketsandMarkets, the global air circuit breaker market is projected to reach $10.5 billion by 2025, driven by increasing demand for efficient power distribution systems.

Leading manufacturers such as Schneider Electric, ABB, and Siemens offer a range of ACB products that feature advanced protection mechanisms and smart technology integration. These distinctions can significantly affect the overall functionality and safety of your electrical infrastructure.

Schneider Electric's ACBs, for instance, are renowned for their EcoStruxure technology, which enhances energy efficiency and provides real-time monitoring. In contrast, ABB emphasizes their ACBs' compact design and low operating costs, catering to spaces with limited installations. Similarly, Siemens positions its ACBs with robust safety features, including integrated surge protection and arc flash detection, ensuring compliance with international safety standards. Evaluating these unique selling propositions alongside the specific requirements of your electrical system will help in making an informed decision that aligns with both performance and budget considerations.

Related Posts

-

Choosing Reliable Manufacturers: Essential Tips and Solutions for Best China Molded Case Circuit Breakers

-

What is the Best Electrical MCCB and Why You Need One for Your Industry

-

7 Essential Tips for Choosing the Best Acb Circuit Breaker for Your Industrial Needs

-

The Future of Innovative Energy Management with Best Air Circuit Breakers

-

Exploring the Unique Features and Applications of Best Thermal Magnetic Circuit Breakers with Practical Usage Tips

-

Revolutionizing Protection Standards for Low Voltage Circuit Breakers in 2030

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500