How to Choose the Right China Molded Case Circuit Breaker for Your Needs

When selecting the appropriate China Molded Case Circuit Breaker (MCCB) for specific applications, it is essential to consider various factors that align with both safety and efficiency. According to Dr. Li Wei, an industry expert in electrical engineering, "Choosing the right MCCB is not just about meeting electrical standards; it's about ensuring longevity and reliability in your electrical systems." This insight underscores the importance of understanding the specific needs of your project, including load requirements, environmental conditions, and regulatory compliance.

The decision-making process for an ideal China Molded Case Circuit Breaker involves careful assessment of parameters such as rated current, interrupting capacity, and installation environment. With advancements in technology and increasing demands for energy efficiency, selecting an MCCB that integrates seamlessly with existing systems has never been more crucial. As the industry evolves, being informed about the latest innovations and compliance standards can significantly impact the safety and performance of electrical systems.

In conclusion, navigating the complexities of choosing the right China Molded Case Circuit Breaker warrants expertise and knowledge. By leveraging insights from professionals like Dr. Li Wei, stakeholders can make informed choices that enhance operational safety and effectiveness, ensuring that their electrical infrastructure is well-equipped for future challenges.

Understanding the Basics of China Molded Case Circuit Breakers

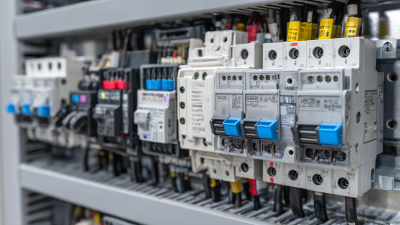

Molded case circuit breakers (MCCBs) are essential components in electrical distribution systems, providing overcurrent protection and ensuring the safety of electrical installations. Understanding the basic functionalities of MCCBs is crucial for selecting the right product for your specific needs. These devices are designed to interrupt the flow of electricity in the event of overloads or short circuits, minimizing potential damages or hazards. According to the International Electrotechnical Commission (IEC), modern MCCBs are available with adjustable trip settings, which enhance their adaptability across various applications, from industrial setups to commercial environments.

When choosing a molded case circuit breaker, it's important to consider key factors such as voltage rating, current carrying capacity, and the environment where the circuit breaker will be installed. Data from recent market research indicates a growing demand for MCCBs capable of handling higher load capacities, reflecting the increasing complexity of electrical systems. In addition, compliance with regional standards, such as those from the National Electrical Manufacturers Association (NEMA), ensures that the selected circuit breaker meets safety and reliability requirements.

Tips: Always assess the specific requirements of your electrical system before purchasing an MCCB. Pay close attention to the breaking capacity, which should match or exceed the potential fault current in your system to prevent failure. Additionally, consider opting for MCCBs with digital interfaces for enhanced monitoring and management capabilities, offering insights into performance metrics that help in proactive maintenance.

Key Factors to Consider When Selecting a Molded Case Circuit Breaker

When selecting a molded case circuit breaker (MCCB), several key factors should be considered to ensure optimal performance and safety for your electrical system. The first factor is the rated current of the MCCB, which needs to match the load requirements of your application. According to a recent industry report from the NEMA, choosing the correct rating can enhance the lifespan of the equipment while providing adequate protection against overload and short circuits.

Another critical consideration is the breaking capacity, which indicates how much fault current the breaker can interrupt without failing. As per the IEC standards, the chosen MCCB must have a breaking capacity that exceeds the potential fault current at the point of installation. This ensures that the circuit breaker can effectively manage unexpected surges, safeguarding both the electrical infrastructure and connected devices.

Tips: Always consult with a qualified electrical engineer to assess your specific needs and calculate the necessary specifications. Additionally, consider the environmental factors at the installation site—temperature fluctuations, moisture levels, and dust exposure can all impact the performance of your circuit breaker. Ensuring proper installation and regular maintenance checks can further enhance the reliability and efficiency of your chosen MCCB.

Evaluating the Electrical Ratings and Specifications Needed

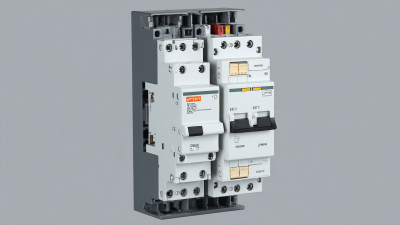

When selecting a molded case circuit breaker (MCCB) for your electrical needs, understanding the electrical ratings and specifications is crucial. The primary ratings to consider include the current rating, voltage rating, and interrupting capacity. The current rating indicates the maximum load that the circuit breaker can handle without tripping. It's essential to select a breaker that matches or slightly exceeds the load requirements of your electrical circuit to ensure reliable operation.

In addition to current and voltage ratings, one must also consider the interrupting capacity of the MCCB. This specification indicates the maximum fault current that the breaker can interrupt safely. An adequately rated MCCB protects your electrical system from overcurrents and short circuits, preventing potential damage to equipment and ensuring user safety. Additionally, features such as thermal and magnetic trip settings provide extra layers of protection, allowing for tailored responses to varying electrical conditions. Therefore, a careful evaluation of these specifications ensures that you select the right molded case circuit breaker that aligns with your specific application and safety requirements.

Assessing the Application Environment and Installation Requirements

When selecting the right molded case circuit breaker (MCCB) for a specific application, it is crucial to thoroughly assess the application environment and installation requirements. One of the primary considerations is the environmental conditions where the circuit breaker will be installed. According to a report by the International Electrotechnical Commission (IEC), factors such as temperature, humidity, and potential exposure to dust or chemicals can significantly impact the performance and longevity of MCCBs. For instance, MCCBs designed for industrial settings typically require enclosures rated for increased ingress protection (IP) to withstand harsh conditions, ensuring reliable operation.

Another important factor is the electrical load and the operating frequency of the circuit. Industry standards suggest that MCCBs should not only be selected based on their current ratings but also on their ability to handle short-circuit conditions and overloads specific to the application. A comprehensive study by the National Electrical Manufacturers Association (NEMA) highlights that improperly sized MCCBs can lead to premature failures or inadequate protection, emphasizing that proper sizing based on application-specific data is crucial. Additionally, installation requirements such as space constraints and accessibility for maintenance should also be taken into account to facilitate efficient operations and timely interventions when needed.

Comparing Brands and Models for Quality and Reliability

When selecting a molded case circuit breaker (MCCB), it's essential to compare various brands and models to find the one that meets your reliability and quality requirements. A good starting point is to assess the specifications of each model. Look for features such as interrupting capacity, thermal-magnetic protection, and adjustable settings. These specifications significantly impact the breaker’s performance and its ability to protect against overloads and short circuits.

Additionally, consider the reputation and track record of the manufacturers. Research customer reviews and feedback to gauge the experiences of others who have used the MCCBs in similar applications. Look for consistency in performance, ease of installation, and quality of customer support. These factors can play a significant role in long-term satisfaction and the potential for replacement in the event of a failure. By carefully comparing these elements across different brands and models, you ensure that you make a well-informed decision tailored to your specific needs.

How to Choose the Right China Molded Case Circuit Breaker for Your Needs - Comparing Brands and Models for Quality and Reliability

| Model | Rated Current (A) | Breaking Capacity (kA) | Weight (kg) | Temperature Range (°C) | Standards Compliance |

|---|---|---|---|---|---|

| MCCB-100A | 100 | 25 | 15 | -10 to 40 | IEC 60947 |

| MCCB-160A | 160 | 36 | 18 | -10 to 40 | IEC 60947 |

| MCCB-250A | 250 | 50 | 20 | -10 to 40 | IEC 60947 |

| MCCB-400A | 400 | 65 | 25 | -10 to 40 | IEC 60947 |

Related Posts

-

The Evolution of Molded Case Circuit Breakers in a Global Market

-

7 Best Molded Case Circuit Breakers for Optimal Circuit Protection

-

Finding the Right Supplier for the Best China Air Circuit Breaker Made Easy

-

Innovative Applications of China Air Circuit Breaker in Modern Electrical Infrastructure

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

Understanding the Importance of MCCB Moulded Case Circuit Breakers in Modern Electrical Systems

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500