Why You Should Choose Electronic MCCB for Reliable Circuit Protection

In today's fast-paced and technology-driven world, the demand for reliable and efficient electrical protection solutions has never been greater. With environmental concerns and energy efficiency taking center stage, the importance of advanced circuit protection devices like Electronic MCCBs (Molded Case Circuit Breakers) is becoming increasingly clear. According to a recent report by MarketsandMarkets, the global market for MCCBs is projected to reach $8.3 billion by 2025, driven by ongoing advancements in electrical safety standards and the push towards smart grid technologies.

Renowned industry expert Dr. John Roberts, a prominent electrical engineer at the Institute of Electrical and Electronics Engineers (IEEE), emphasizes the significance of adopting Electronic MCCBs in modern installations. He states, "The transition to Electronic MCCBs not only enhances operational reliability but also provides critical data insights that help in predictive maintenance and energy optimization." This technological evolution reflects a significant step forward in ensuring that electrical systems can cope with increasing loads and unpredictable surges, ultimately safeguarding both infrastructure and investments.

Renowned industry expert Dr. John Roberts, a prominent electrical engineer at the Institute of Electrical and Electronics Engineers (IEEE), emphasizes the significance of adopting Electronic MCCBs in modern installations. He states, "The transition to Electronic MCCBs not only enhances operational reliability but also provides critical data insights that help in predictive maintenance and energy optimization." This technological evolution reflects a significant step forward in ensuring that electrical systems can cope with increasing loads and unpredictable surges, ultimately safeguarding both infrastructure and investments.

As we explore the top reasons to choose Electronic MCCBs over traditional alternatives, it becomes evident that this innovative solution is not merely a trend but a necessary evolution in the quest for safer, more efficient electrical systems. The future is undeniably tied to the capabilities of Electronic MCCBs, offering superior protection and management of electrical circuits.

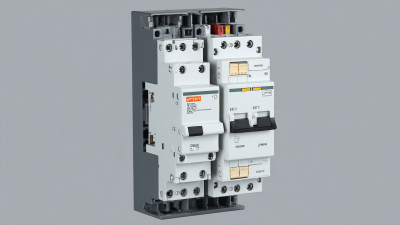

Benefits of Electronic MCCBs over Traditional Circuit Breakers

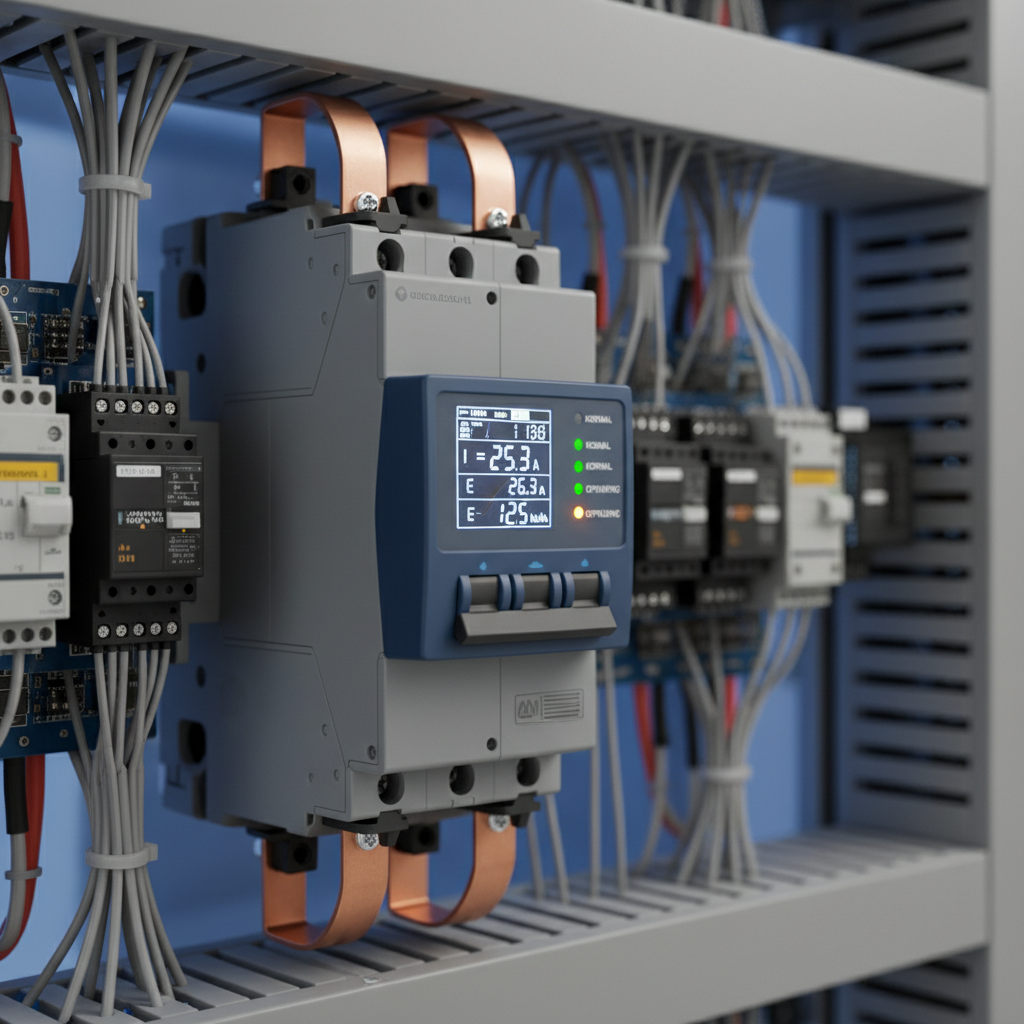

Electronic Molded Case Circuit Breakers (MCCBs) are rapidly gaining traction due to their numerous advantages over traditional mechanical circuit breakers. One key benefit is the enhanced monitoring and control capabilities offered by electronic MCCBs. These devices provide real-time data on electrical loads, making it easier to identify potential issues before they lead to circuit failures. Unlike traditional breakers that merely cut off the current during overload, electronic MCCBs can adjust their sensitivity settings based on operational conditions, significantly improving reliability and reducing downtime.

Moreover, the circuit breaker market in Europe is projected to reach USD 3.23 billion by 2033, with Germany currently holding a notable 23.9% share of the market. This reflects a strong shift towards advanced electrical protection solutions, including electronic MCCBs, driven by the increasing complexity of electrical systems and the demand for improved safety measures. As organizations seek to integrate distributed generation and microgrid technologies, the flexibility and adaptability of electronic MCCBs present a vital solution to the challenges faced by traditional protection systems, ensuring not only operational efficiency but also enhanced longevity and performance in safeguarding electrical circuits.

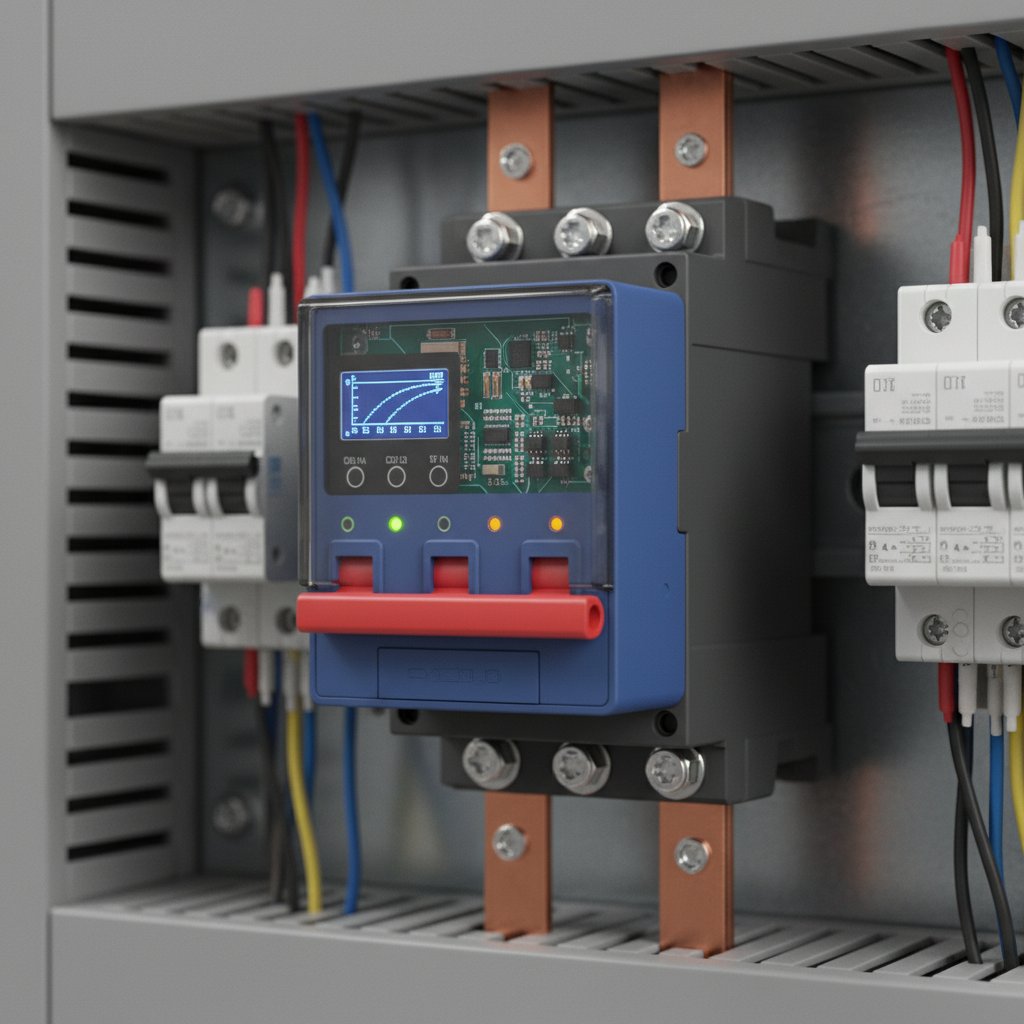

Enhanced Precision in Fault Detection and Response Times

In the realm of circuit protection, electronic molded case circuit breakers (MCCBs) stand out due to their enhanced precision in fault detection and response times. According to a report by the International Electrotechnical Commission (IEC), electronic MCCBs can detect faults and initiate circuit interruption in less than 30 milliseconds, significantly faster than traditional thermal magnetic breakers, which can often take hundreds of milliseconds. This rapid response is crucial, especially in industrial settings where equipment can be sensitive to overcurrents, leading to irreversible damage.

Moreover, the precision of electronic MCCBs extends to their ability to differentiate between various types of faults, such as overloads and short circuits. This is supported by findings from a study conducted by the National Electrical Manufacturers Association (NEMA), which notes that electronic MCCBs offer a fault detection accuracy of up to 98%. This high level of accuracy not only minimizes downtime but also enhances the overall safety of electrical systems by preventing nuisance tripping, ensuring that circuits are only interrupted when truly necessary. By opting for electronic MCCBs, industries can effectively safeguard their operations while maintaining optimal performance levels.

Reliability of Electronic MCCB in Circuit Protection

This chart illustrates the enhanced precision in fault detection and response times of Electronic Molded Case Circuit Breakers (MCCBs) compared to traditional MCCBs, showcasing their reliability in circuit protection.

User-Friendly Features of Modern Electronic MCCBs

Modern Electronic Molded Case Circuit Breakers (MCCBs) offer a range of user-friendly features that enhance reliability and convenience in electrical protection. One significant advantage is their digital monitoring capabilities. According to a recent report by Research and Markets, the global MCCB market is projected to reach $2.9 billion by 2027, driven largely by advancements in electronic technology that provide real-time monitoring and diagnostics. This allows users to identify issues before they escalate, ensuring minimal downtime and improved safety.

Furthermore, contemporary electronic MCCBs feature customizable settings that allow users to tailor protection levels based on specific applications. This adaptability is crucial; as noted by the International Electrotechnical Commission, improper settings account for 30% of electrical failures. Electronic MCCBs come equipped with user interfaces that simplify the adjustment of trip settings and provide instant feedback on circuit performance. Enhanced communication protocols enable integration with building management systems, further streamlining the operation and monitoring of electrical systems. These innovations underscore the shift toward more intelligent, responsive electrical solutions that prioritize user-friendliness and operational efficiency.

Energy Efficiency and Cost-Effectiveness in Electrical Systems

When considering circuit protection solutions, electronic molded case circuit breakers (MCCBs) stand out not only for their reliability but also for their energy efficiency and cost-effectiveness. According to a report by the International Energy Agency (IEA), improper circuit protection can lead to up to 30% energy loss in electrical systems. Electronic MCCBs offer advanced thermal and short-circuit protection that minimizes energy waste while enhancing overall system reliability. Unlike traditional MCCBs, these electronic versions can precisely measure and adjust the current usage, thereby optimizing energy consumption.

Furthermore, the initial investment in electronic MCCBs can be offset by their long-term savings. According to the National Electrical Manufacturers Association (NEMA), implementing electronic MCCBs can lead to significant reductions in electrical maintenance costs, with estimates suggesting a decrease of 15-20% in operational expenses over their life cycle. Additionally, their ability to provide timely fault detection and remote monitoring capabilities further enhances operational efficiency, reducing downtime and consequential losses. In a market that increasingly prioritizes sustainability, the shift to electronic MCCBs marks an important step towards achieving more energy-efficient electrical systems.

Long-Term Reliability and Maintenance Considerations for MCCBs

When considering circuit protection, the long-term reliability of Molded Case Circuit Breakers (MCCBs) is paramount. Electronic MCCBs offer advanced features that enhance durability and minimize the likelihood of failure over extended periods. Unlike traditional thermal magnetic MCCBs, electronic versions employ sophisticated microprocessor technology to monitor electrical parameters continuously. This capability allows them to respond more quickly to overloads and short circuits, reducing the risk of damage to both the circuit and connected equipment.

Maintenance is another critical factor when choosing MCCBs. Electronic MCCBs typically require less frequent servicing compared to their electromechanical counterparts. Their design minimizes wear and tear, which translates to lower maintenance costs and reduced downtime. Furthermore, many electronic models are equipped with self-diagnostic features that alert users to potential issues before they escalate, thus ensuring continuous and reliable operation. Overall, selecting electronic MCCBs not only enhances circuit protection but also contributes to a more efficient and cost-effective maintenance strategy, making them a wise choice for long-term reliability.

Related Posts

-

Resilient Growth of Chinese-Made Best Electronic MCCBs Amidst US-China Tariff Strife: An Industry Analysis

-

Understanding the Importance of MCCB Moulded Case Circuit Breakers in Modern Electrical Systems

-

Exploring the Spectrum: Real-World Applications and Innovations in Electrical MCCBs

-

How to Select the Right MCCB Molded Case Circuit Breaker for Your Electrical System's Needs

-

How to Choose the Right MCCB Circuit Breaker for Your Industrial Needs: Key Factors and Data Insights

-

The Ultimate Guide to Mastering Electronic MCCB for Your Industrial Applications

JCB1-125

JCB1-125 JCB2-40M

JCB2-40M JCB3-63DC

JCB3-63DC JCB3-80H

JCB3-80H JCB3-80M

JCB3-80M JCBH-125

JCBH-125 JC125-4P

JC125-4P JCMX

JCMX JCSD

JCSD JCOF

JCOF JCMX1-125

JCMX1-125 JCOF1-125

JCOF1-125 JCSD1-125

JCSD1-125 JCR3HM

JCR3HM JCRD2-125

JCRD2-125 JCRD4-125

JCRD4-125 JCRB2-100

JCRB2-100 JC3RH-2P

JC3RH-2P JC3RH-S

JC3RH-S JC3RH-B

JC3RH-B JC3RH-BS

JC3RH-BS JCR2-63

JCR2-63 JCR1-40

JCR1-40 JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-80M

JCB2LE-80M JCB2LE-40M

JCB2LE-40M JCB1LE-125

JCB1LE-125 JCB3LM-80

JCB3LM-80 JCH2-125

JCH2-125 JCH2-125

JCH2-125 CJX2

CJX2 CJ19

CJ19 JCMCU

JCMCU JCHA

JCHA JCSD-40

JCSD-40 JCSD-60

JCSD-60 JCSP-40

JCSP-40 JCSP-60

JCSP-60 JCSPV

JCSPV WEW1-1000

WEW1-1000 WEW1-1600

WEW1-1600 WEW1-2000

WEW1-2000 WEW1-3200

WEW1-3200 WEW1-4000

WEW1-4000 WEW1-6300

WEW1-6300 DC6-125

DC6-125 AX-400-1250

AX-400-1250 AXAL-400-1250A

AXAL-400-1250A AL-400-1250

AL-400-1250 DC3-160

DC3-160 AXS-400-1250A

AXS-400-1250A SHT-125-160

SHT-125-160 UVT-125-160A

UVT-125-160A P-250A-3P-A

P-250A-3P-A 400-3P/4P terminal cover

400-3P/4P terminal cover 1250-3Pmccb accessories busbar

1250-3Pmccb accessories busbar 250-3P terminal conver

250-3P terminal conver WLM6-TCV-160A-3P

WLM6-TCV-160A-3P WLM6-MIP-250A

WLM6-MIP-250A WLM6-125A-3300 3P/4P

WLM6-125A-3300 3P/4P WLM6-160A-3300 3P/4P

WLM6-160A-3300 3P/4P WLM6-250A-3300 3P/4P

WLM6-250A-3300 3P/4P WLM6-400A-3300 3P/4P

WLM6-400A-3300 3P/4P WLM6-630A-3300 3P/4P

WLM6-630A-3300 3P/4P WLM6-800A-3300 3P/4P

WLM6-800A-3300 3P/4P WLM6-1250A-3300 3P/4P

WLM6-1250A-3300 3P/4P WLM6-1600A-3300 3P/4P

WLM6-1600A-3300 3P/4P WLM6-2000A 3P/4P

WLM6-2000A 3P/4P WLM8-125H-3300

WLM8-125H-3300 WLM8-250H-3300

WLM8-250H-3300 WLM8-400H-3300

WLM8-400H-3300 WLM8-400H-4300

WLM8-400H-4300 WLM8-630H-3300

WLM8-630H-3300 WLM8-630H-4300

WLM8-630H-4300 WLM6RT-125A

WLM6RT-125A WLM6RT-160A

WLM6RT-160A WLM6RT-250A

WLM6RT-250A WLM6RT-400A

WLM6RT-400A WLM6RT-630A

WLM6RT-630A WLM6RT-800A

WLM6RT-800A WLM6RT-1250A

WLM6RT-1250A WLM6E-160A-3300 3P

WLM6E-160A-3300 3P WLM6E-250A-3300

WLM6E-250A-3300 WLM6E-400A-3300 3P/4P

WLM6E-400A-3300 3P/4P WLM6E-630A-3300

WLM6E-630A-3300 WLM6E-800A-3300 3P/4P

WLM6E-800A-3300 3P/4P WLM6E-1250A-3300

WLM6E-1250A-3300 WLM6E-1600-3300 3P/4P

WLM6E-1600-3300 3P/4P WLM6E-2000A-3300 3P/4P

WLM6E-2000A-3300 3P/4P WLM8E-250H-3300

WLM8E-250H-3300 WLM8E-400H-3300

WLM8E-400H-3300 WLM8E-400H-4300

WLM8E-400H-4300 WLM8E-630H-3300

WLM8E-630H-3300 WLM8E-630H-4300

WLM8E-630H-4300 WLM6EY-250-3300 3P/4P

WLM6EY-250-3300 3P/4P WLM6EY-400 3P/4P

WLM6EY-400 3P/4P WLM6EY-630 3P/4P

WLM6EY-630 3P/4P WLM6EY-800A 3P/4P

WLM6EY-800A 3P/4P WLM6EY-1250A 3P/4P

WLM6EY-1250A 3P/4P WLM6ELY-160A

WLM6ELY-160A WLM6ELY-250A

WLM6ELY-250A WLM6ELY-400A

WLM6ELY-400A WLM6ELY-800A

WLM6ELY-800A WLM6ELY-1250A

WLM6ELY-1250A WLM8EY-250H-3300

WLM8EY-250H-3300 WLM8EY-400H-3300

WLM8EY-400H-3300 WLM8EY-630H-3300

WLM8EY-630H-3300 WLM6LY-125A

WLM6LY-125A WLM6L-160A

WLM6L-160A WLM6LY-250A

WLM6LY-250A WLM6LY-400A

WLM6LY-400A WLM6LY-800A

WLM6LY-800A WLM6LY-630A

WLM6LY-630A WLM6LY-1250A

WLM6LY-1250A WLM8LY-125H-3300

WLM8LY-125H-3300 WLM8LY-250H-3300

WLM8LY-250H-3300 WLM8LY-400H-3300

WLM8LY-400H-3300 WLM8LY-630H-3300

WLM8LY-630H-3300 JCB3-63DC

JCB3-63DC JCB1-125DC

JCB1-125DC WLM7DC-250A-2300 2P/3P

WLM7DC-250A-2300 2P/3P WLM7DC-315A-3300 2P/3P

WLM7DC-315A-3300 2P/3P WLM7DC-400A-2300 2P/3P

WLM7DC-400A-2300 2P/3P WLM7DC-630A-3300 3P

WLM7DC-630A-3300 3P WLM7DC-800A-2300 2P/3P

WLM7DC-800A-2300 2P/3P WLM7DC-400A 2300

WLM7DC-400A 2300 WLM7DC-630A-2300 2P

WLM7DC-630A-2300 2P WLM7HU-250-3300 3P

WLM7HU-250-3300 3P WLM7HU-315-3300 3P

WLM7HU-315-3300 3P WLM7HU-400-3300 3P

WLM7HU-400-3300 3P WLM7HU-630-3300 3P

WLM7HU-630-3300 3P WLM7HU-800-3300 3P

WLM7HU-800-3300 3P PV-1500V/250A

PV-1500V/250A WEW3-1600

WEW3-1600 WEW3-2500

WEW3-2500 WEW3-4000

WEW3-4000 WEW3-7500

WEW3-7500